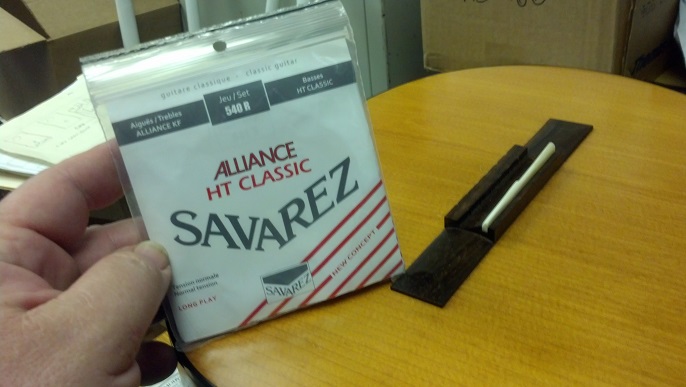

Donny mentioned that this beautiful 1970s era Yamaha needed a set of strings. Turns out, it could use a little TLC. The Unbrokenstring Crew steps up to the plate to bring this classical guitar up to speed!

Intended as a student guitar, these wonderful old Yamaha guitars rival many medium priced guitars found today.

The serial number is hand-stamped on a soundboard brace.

At the time, we considered Made In Taiwan as junk. Nowadays, that was the Good Stuff! How times change…

Obviously the nut is unglued, but note that the rosewood fingerboard had been painted black, to give the appearance of ebony. Such was the snobbery found in the classical guitar world back in the 1970’s. My first classical guitar sported a black painted fingerboard, and it looked a lot like this after years of playing. Nothing to be ashamed of nowadays. In another fifty years, we’ll be playing guitars with synthetic Richlite fingerboards, and consider rosewood fingerboards as ‘high end’ and collectible.

This diamond file is removing the old glue and truing up the gluing surface on the neck.

The diamond file is working on the end grain of the fingerboard. That little cavity under the nut is not for a truss rod, but rather appears to be a slot for a stiffener of some sort. Classical guitars seldom use truss rods to counteract string tension, as nylon string tension is about a third of the tension created by steel strings.

Any glue remaining on the nut itself comes off using the mill file.

Some alcohol on a rag cleans off residue on the nut.

Time to clear out the old DNA and tune up the string slots in the nut.

This is a serrated wire used to clean orifices on cutting torch tips. They are often re-sold for many times the price by companies servicing the luthier craft. Just get yours from the car parts store or a good tool store.

The tip cleaners come in many sizes, so just use a micrometer to select the correct size for your application. Here, I’ve moved to the B string. The rest of the slots are clean and smooth, so I’m done here once this slot is smooth.

Looks good! We’re ready for some hide glue. But how do I clamp it down?

How about using a couple of the old strings, brought up to tension, to keep the nut in place for a day or so?

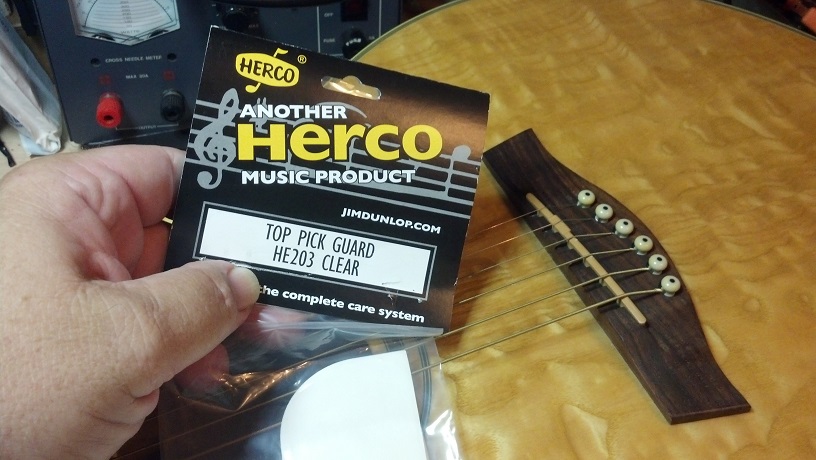

This guitar was missing the saddle. Here, I’m shaping a piece of Vietnamese water buffalo bone on the belt sander.

The water buffalo bone is incredibly hard, a natural material, and a renewable resource as opposed to ivory. Some of the new synthetics are good, but I have this in stock and I love grossing out the other Unbrokenstring Crew members. Bone? Dead animals? Yuck!

The Yamaha saddle is about 0.100 inch thick. These blanks are about 0.140 inch thick to start. After a few minutes, I’m down to 0.137 inch.

We are at 0.131 inch.

Down to 0.121 inch.

Can you read this one? 0.115 inch.

Almost there! We’re at 0.103 inch thick.

As George Bush would say, we have destinated!

The trial-fit part of our program is complete. Note that the saddle is a little long. There is a method in my madness here. Let me introduce you to a real luthier who can explain what I’m trying to accomplishing here:

Q: Why do the British like Lucas refrigerators?

A: Because they like warm beer.

Seriously, the last thing I want to use on a fine musical instrument is lubricant that oxidizes and turns into gum. Synthetic lubricants don’t oxidize, and so make a better choice when metal-to-metal lubrication is needed. Such as in tuning machines. This Lucas product is thick enough to stay in place when assembling engines. This lubricant will stay in place on a musical instrument.

I need to install some strings in order to set the action at the twelfth fret. Before I do much more with these tuning machines, I will lubricate them and set the gear mesh so that the guitar will stay in tune yet the tuners will run smoothly.

I re-used a couple of the old strings to accomplish the string height setup. One of them has a ball end!

Stupid Me. The old strings were worn and did not have a constant cross section. Thus, I got weird, inconsistent readings. I’ll use a new string.

Same with the high E string. A new string is pressed into service in order to complete the setup.

The top edge of the saddle will be rounded off in order to remove any sharp edges that may cut the strings. A rounded top edge also allows a single point to support the string, resulting in better sustain.

Now that we have the saddle to the proper dimensions, every surface will be polished with a high speed buffer.

The bottom edge of the saddle blank gets special attention. Here the blank is set level with the jaws of the vise. The jaws will act as a guide to keep everything straight and true. A polished, flat surface against the bridge will permit the best transfer of energy from the strings to the soundboard. The variation in color in this piece of bone is due to the changes in orientation of the grain of the calcium in the bone. This gives an almost opalescent appearance to the saddle.

The top of the blank is polished, yielding a hard surface to support the strings. Note that this end of the blank is curved. This marks the orientation of the saddle; the rounded end points in the direction of string 1 (high E.)

The faces of the saddle are polished as well, mainly for appearance. Note again the presence of the calcium grain.

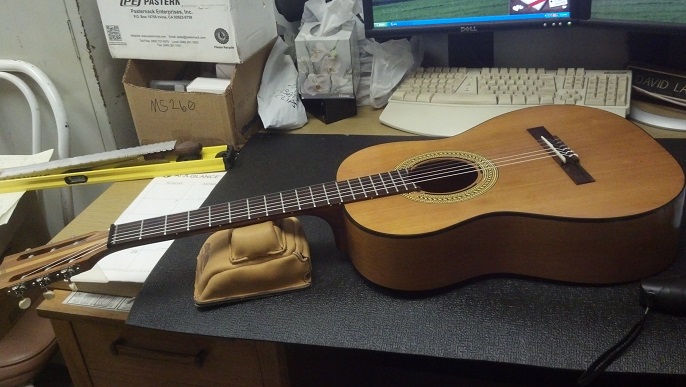

Time to string it up. Here you can see the wedge shape of the saddle, which allows the user to set the action height.

All laced up! The free end of the adjacent string is secured in the loop of the next string over. I’ve never had to retie a string or tie an additional knot when tying the string ends off in this manner.

She plays beautifully and the intonation is perfect!

Thanks for reading all the way to the end!

David Latchaw EE

281-636-8626