A secret weapon of many an acoustic and jazz artist, this mid-seventies line of Yamaha solid state amps were well-regarded among those few who knew about them. This like-new specimen had been suffering from a strange ailment, then went mute. Could the Unbrokenstring Crew revive this unit?

On the exterior, this amp was in very good shape considering that it had been built forty years ago!

On the exterior, this amp was in very good shape considering that it had been built forty years ago!

Starting our tour, the power switch combines the ON/OFF function with the AC polarity reversal switch seen on many tube amps of the same period.

Starting our tour, the power switch combines the ON/OFF function with the AC polarity reversal switch seen on many tube amps of the same period.

The high and low level input jacks are typical for the era.

The high and low level input jacks are typical for the era.

The tone stack includes a ‘bright’ function, a precursor of the ‘presence’ control seen on amplifiers today.

The tone stack includes a ‘bright’ function, a precursor of the ‘presence’ control seen on amplifiers today.

The presence of the reverb function demonstrates that this is an early unit. Many of the later ones did not have a reverb tank at all. The distortion function is an attempt to add ‘fuzz’ and is nothing like the metal/shred distortion heard today.

The presence of the reverb function demonstrates that this is an early unit. Many of the later ones did not have a reverb tank at all. The distortion function is an attempt to add ‘fuzz’ and is nothing like the metal/shred distortion heard today.

A few attempts had been made over the years to clean the controls. Unfortunately, the lube spread onto the front panel around the controls. Yuck!

A few attempts had been made over the years to clean the controls. Unfortunately, the lube spread onto the front panel around the controls. Yuck!

The open cabinet is clean and functional.

The open cabinet is clean and functional.

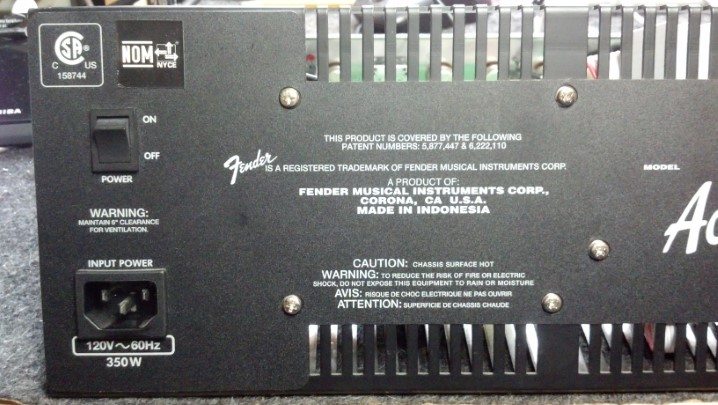

We have the usual name-rank-serial number information here.

We have the usual name-rank-serial number information here.

We have two unmarked jacks. What in the world? But we see foot switch jacks which are not out of the ordinary.

We have two unmarked jacks. What in the world? But we see foot switch jacks which are not out of the ordinary.

Both the AC power into the unit and the DC power to the final amplifier block are externally fused.

Both the AC power into the unit and the DC power to the final amplifier block are externally fused.

And, we have a QC sticker!

And, we have a QC sticker!

Removing one of the rear baffles reveals the solid state amp and gives us access to the chassis.

Removing one of the rear baffles reveals the solid state amp and gives us access to the chassis.

Obviously the original loudspeaker, the response graph demonstrates the heritage of this unit to the high fidelity world that Yamaha dominated in the 1970s.

Obviously the original loudspeaker, the response graph demonstrates the heritage of this unit to the high fidelity world that Yamaha dominated in the 1970s.

This ground lead connected the chassis of the amplifier to the frame of the loudspeaker.

This ground lead connected the chassis of the amplifier to the frame of the loudspeaker.

With the chassis out of the cabinet, we see a reverb tank in the foreground, a power transformer to the right, big capacitors in the center, and a mono-block amplifier to the left rear.

With the chassis out of the cabinet, we see a reverb tank in the foreground, a power transformer to the right, big capacitors in the center, and a mono-block amplifier to the left rear.

This strain relief for the AC power cord is really over-the-top!

This strain relief for the AC power cord is really over-the-top!

The black, finned heat sink is the foundation upon which the power amplifier is built.

The black, finned heat sink is the foundation upon which the power amplifier is built.

This large electrolytic filters the DC power for the amplifier, which is nominally 80vdc.

This large electrolytic filters the DC power for the amplifier, which is nominally 80vdc.

This electrolytic capacitor is in series between the amplifier output and the loudspeaker. This amplifier’s circuit topography shifts the DC operating point of the amplifier to one-half of the DC power supply voltage, effectively forming a class AB amplifier using a single power supply. This capacitor passes the audio current to the loudspeaker while protecting the loudspeaker from any DC current.

This electrolytic capacitor is in series between the amplifier output and the loudspeaker. This amplifier’s circuit topography shifts the DC operating point of the amplifier to one-half of the DC power supply voltage, effectively forming a class AB amplifier using a single power supply. This capacitor passes the audio current to the loudspeaker while protecting the loudspeaker from any DC current.

Underneath the chassis we find this fused, low-voltage power supply which supplies floating DC voltages for the circuitry.

Underneath the chassis we find this fused, low-voltage power supply which supplies floating DC voltages for the circuitry.

Remember those two unmarked jacks on the rear panel? Someone added them so that a quarter inch cable can be connected to another quarter inch cable. Yes, this is a home-made 1/4″ mono to 1/4″ mono jack adapter/coupler.

Remember those two unmarked jacks on the rear panel? Someone added them so that a quarter inch cable can be connected to another quarter inch cable. Yes, this is a home-made 1/4″ mono to 1/4″ mono jack adapter/coupler.

Here is the bottom side of the two large electrolytic capacitors we saw up top.

Here is the bottom side of the two large electrolytic capacitors we saw up top.

More fuses and bypass capacitors are visible here, in vinyl tubing, to shroud the terminals from touching something they shouldn’t.

More fuses and bypass capacitors are visible here, in vinyl tubing, to shroud the terminals from touching something they shouldn’t.

The ON/OFF/ON switch is seen to the right and the Power ON indicator lamp, with limiting resistor, are seen here.

The ON/OFF/ON switch is seen to the right and the Power ON indicator lamp, with limiting resistor, are seen here.

Look at the thick steel shield that keeps any signals running around the inside of the amplifier away from the input jacks!

Look at the thick steel shield that keeps any signals running around the inside of the amplifier away from the input jacks!

While we’re here, let’s service the unit. Jacks are cleaned with De-Ox-It.

While we’re here, let’s service the unit. Jacks are cleaned with De-Ox-It.

This circuit board handles all the signals surrounding the front-panel potentiometers.

This circuit board handles all the signals surrounding the front-panel potentiometers.

These controls will be properly cleaned and re-lubricated. And we can clean that nasty front panel while we’re here!

These controls will be properly cleaned and re-lubricated. And we can clean that nasty front panel while we’re here!

After removing two large bolts, the power amp assembly lifts off.

After removing two large bolts, the power amp assembly lifts off.

The six pin connector handles power in, signal in, and amplified signal out duties.

The six pin connector handles power in, signal in, and amplified signal out duties.

Inside this assembly, we see all the components for a transistor-based solid state power amplifier.

Inside this assembly, we see all the components for a transistor-based solid state power amplifier.

A pair of these transistors handle the power amp duties. The screen separates everything from the collector of the transistors, which are at +80vdc potential.

A pair of these transistors handle the power amp duties. The screen separates everything from the collector of the transistors, which are at +80vdc potential.

This screw under the little bump in the sheet metal holds a temperature-compensating diode array in close contact with the heat sink. This diode array provides temperature compensation for the transistorized amplifier.

This screw under the little bump in the sheet metal holds a temperature-compensating diode array in close contact with the heat sink. This diode array provides temperature compensation for the transistorized amplifier.

Note that this module is stamped 50W/8 ohms. The Japanese think of everything!

Note that this module is stamped 50W/8 ohms. The Japanese think of everything!

With the cover removed, we can see the inner details.

With the cover removed, we can see the inner details.

These low-level driver transistors are pure unobtanium, which means that if they are bad, there is no modern direct replacement.

These low-level driver transistors are pure unobtanium, which means that if they are bad, there is no modern direct replacement.

Fortunately, all of those low-level driver transistors appear to be OK. The curve tracer indicates that this is a PNP device.

Fortunately, all of those low-level driver transistors appear to be OK. The curve tracer indicates that this is a PNP device.

This is another bit of pure unobtanium. Three silicon diodes with special forward voltage characteristics over temperature are housed in this component.

This is another bit of pure unobtanium. Three silicon diodes with special forward voltage characteristics over temperature are housed in this component.

This diode array appears to be functional for now. These are HIGHLY SOUGHT AFTER by techs who rebuild those 1970’s era Kenwood and Pioneer stereo receivers.

This diode array appears to be functional for now. These are HIGHLY SOUGHT AFTER by techs who rebuild those 1970’s era Kenwood and Pioneer stereo receivers.

Every component will be checked, including the power transistors. Replacements are available for these, if we need them.

Every component will be checked, including the power transistors. Replacements are available for these, if we need them.

Almost every component will be removed from the circuit board and verified against the schematic and the markings on the device.

Almost every component will be removed from the circuit board and verified against the schematic and the markings on the device.

This capacitor was more than 30% low in capacitance, and will be replaced. (No, the leads are not touching.)

This capacitor was more than 30% low in capacitance, and will be replaced. (No, the leads are not touching.)

With the power amp assembly back together, we can perform some initial setup of voltages and levels.

With the power amp assembly back together, we can perform some initial setup of voltages and levels.

One of those two big power transistors with the copper-colored tabs is intermittent. Can we find a matched complimentary pair to replace them both?

One of those two big power transistors with the copper-colored tabs is intermittent. Can we find a matched complimentary pair to replace them both?

Yes, after some research, an adequate replacement was ordered. Whew!

Yes, after some research, an adequate replacement was ordered. Whew!

Here they are, those black boxy devices in the center of the picture. I marked the collector pin locations with a C and the base pin locations with a B on the circuit board so I could get the new parts in the right place.

Here they are, those black boxy devices in the center of the picture. I marked the collector pin locations with a C and the base pin locations with a B on the circuit board so I could get the new parts in the right place.

OK, now we’re cooking. The center yellow trace is a signal called C.VOLT on the schematic, and represents the voltage value of the midpoint of the DC power supply.

OK, now we’re cooking. The center yellow trace is a signal called C.VOLT on the schematic, and represents the voltage value of the midpoint of the DC power supply.

Over a few hours, the value of C.VOLT changed, creating bad distortion. Look closely at the green capacitor at the top of the picture. Can you see something ‘wet’ on the circuit board under it?

Over a few hours, the value of C.VOLT changed, creating bad distortion. Look closely at the green capacitor at the top of the picture. Can you see something ‘wet’ on the circuit board under it?

That ‘wet’ looking stuff is similar to contact cement. The Japanese used this stuff extensively in the 1970s to secure electronic components so that they did not come loose from the circuit boards when shipped to the United States and elsewhere. Over time, this ‘stuff’ becomes conductive, which will upset circuit operation. Many a Japanese-built bit of electronics, including televisions and Ham radios, were taken out of operation by this stuff.

That ‘wet’ looking stuff is similar to contact cement. The Japanese used this stuff extensively in the 1970s to secure electronic components so that they did not come loose from the circuit boards when shipped to the United States and elsewhere. Over time, this ‘stuff’ becomes conductive, which will upset circuit operation. Many a Japanese-built bit of electronics, including televisions and Ham radios, were taken out of operation by this stuff.

The site where the green capacitor goes has been cleaned. This needs to be repeated for any ‘stuff’ remaining in this unit.

The site where the green capacitor goes has been cleaned. This needs to be repeated for any ‘stuff’ remaining in this unit.

Here is the C.VOLT test point. The crusty brown stuff is solder flux, which will also be removed.

Here is the C.VOLT test point. The crusty brown stuff is solder flux, which will also be removed.

I uploaded a video of the working amplifier to YouTube, which then blocked the video and hit me with a take-down notice about a minute after I uploaded it. The audio content of the video was copyrighted, and I was caught. Don’t you just love YouTube/Google/Facebook?

Thanks for reading all the way to the end!

CONTACT – David Latchaw EE

281-636-8626