This straight-ahead Ibanez four-string bass will become a springboard for a bassist to expand his musical horizons. Can the Unbrokenstring Crew turn this into a fretless bass? Let’s find out!

Because this will be a training tool and not a piece of performance art, the customer wanted the fret channels and position dots to remain visible. Maple, a contrasting wood will fill the fret slots. The maple veneer is coiled up in the yellow box next to the bass.

Because this will be a training tool and not a piece of performance art, the customer wanted the fret channels and position dots to remain visible. Maple, a contrasting wood will fill the fret slots. The maple veneer is coiled up in the yellow box next to the bass.

We’ll take one last look at the frets. Say goodbye!

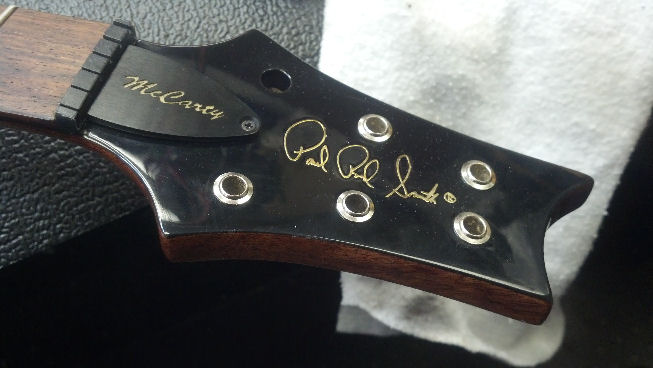

These strings are the original OEM Malaysian strings. These are headed for the recycle bin. The customer also asked that the headstock logo be removed, to add a little mystique. The tuners will be removed and stored.

The tape protects the fret board from me. An Exacto knife clears away the junk from the bottom of the fret to be removed so we can have something to grab.

With a little care, the Exacto knife blade can be pushed under the fret wire to start the removal process. Do Not Attempt This At Home, Kids!

Each fret is heated with the soldering iron.

These Harbor Freight end-nippers have been ground flush and serve as a pretty good set of fret pullers.

What the Exacto knife started, the fret puller finishes.

This takes a few moments so that I don’t tear out the wood around the fret tang.

Houston, we are clear the tower. Rinse, repeat.

These are headed for the recycle bin, along with the strings.

Some Dr. Ducks Ax Wax has just enough petroleum distillates to cut the headstock silkscreen.

The head stock logo yields easily to a little Dr. Duck’s and a little Elbow Grease.

A tiny bit of compound restores the gloss in an even manner. You can’t tell the silk screen was ever there.

Say goodbye to the identification decal, too. What the customer wants, the customer gets!

This was a decal, so it shattered into tiny fragments. Be sure to remember this trick when you steal your next guitar.

Now we move to the maple veneer. The material we are using is sold as edging around laminate counter tops. One face is covered with a thermally-sensitive glue. This glue can be easily removed with some paint stripper.

The stripper was brushed on, then scraped off. This is kinda fun!

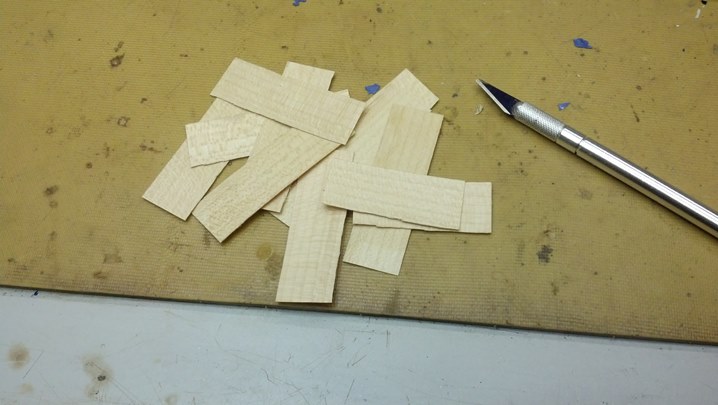

After the paint remover evaporates, we cut the veneer into two and a half inch long strips.

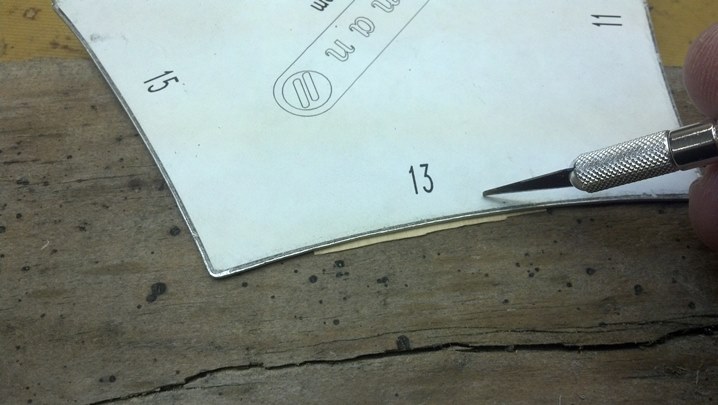

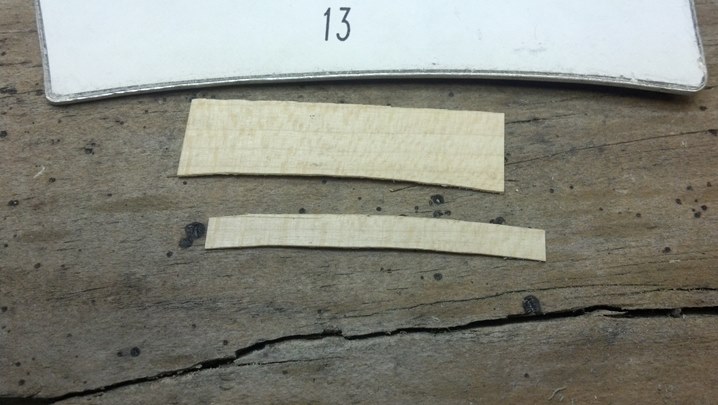

The bottom of the fret board slots are curved at the same radius as the fret board. So I am using this home-made radius gauge as a cutting guide to radius the bottom edge of the maple veneer to match the bottom of the slot.

An Exacto knife makes short work of the veneer. You sharp eyed visitors may note that the Ibanez bass fret board is 14 inch radius, not 13. Leaving the center a little high allows a place for more glue. This radius works perfectly.

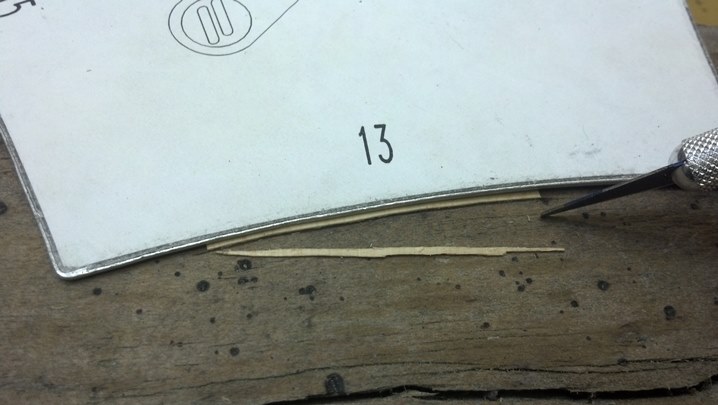

As one edge is cut, the veneer is slipped out from under the radius gauge, and another cut is made.

The fret slots need to be clean and straight. Here, my scraper is just the right size to clear out the slot.

The ends of this scraper were ground square, creating a nice slot cleaner.

The radiused maple veneer pieces were glued into the slots using hide glue.

This looks like an oriental stringed instrument neck.

After the glue dried, I used the end nippers to do most of the coarse trimming. A fret board protector acts as a shim to raise the cutting edges off the face of the fret board.

Next, I’m trying out the Exacto knife on the maple. Nice curly shavings came off the maple filler.

Working from the center of the fret board out, the single edged razor blade was perfect for the final smooth cut. Note that a bit of the glue fillet is being removed here, resulting in a nice flat surface on the fret board.

Here is a closeup of the job the razor blade did on the fret board. This will sand nicely. A final check of the truss rod assures that the fret board is held absolutely straight, no relief or bow of any sort.

This Stanley spirit level has one edge machined to a very precise flat surface.

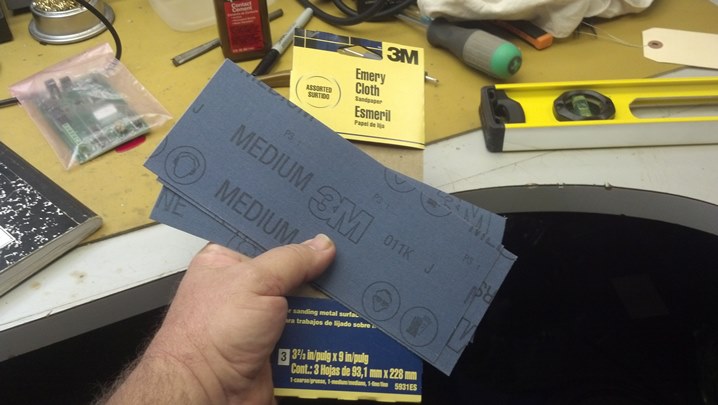

This emery cloth is a very aggressive and durable abrasive medium.

A sheet of emery cloth was cut to fit the machined edge of the spirit level. Now we’re ready to build our own sanding beam.

The emery cloth will take at least two coats of contact cement because the first coat soaks into the cloth.

In case you missed the first one, here is the second coat of contact adhesive

The strips of emery cloth form a continuous abrasive surface along the entire length of the spirit level.

This heavy aluminum fret board gauge is just right to mash out all the air underneath the emery cloth.

The spirit level makes a sanding beam that is the perfect length for this bass fret board. See the dust at the right end?

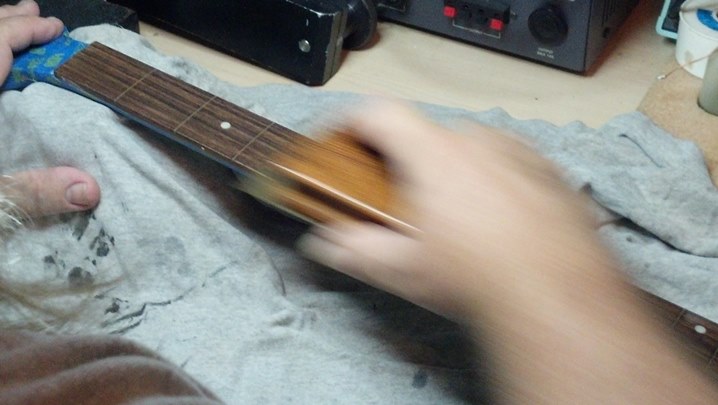

Now that the fret board is straight, we will reestablish the radius of the fret board with this 14 inch radius sanding block.

Radiused and straightened, we’re ready to apply a hard finish to the fret board. Everything that is not fret board is covered with tape. If you hadn’t noticed, the nut was removed prior to sanding.

I didn’t want to put much finish on the end grain at either end of the fret board in order to minimize any swelling or expansion that would spoil the shape of the fret board. When the wood is sealed, I’ll go back and finish the end grain.

The unlabelled can contains Diamond Varathane Floor Finish, a commercial polyurethane finish used in roller rinks and bowling alleys. I discovered this stuff when finishing pine furniture. The Diamond Varathane was the only thing that would stand up to my cat’s desire to chew on the corners of the furniture. Absolutely bullet-proof.

The first ten (yes, that’s TEN) coats were applied with a brush. We are filling a lot of wood pores, you know.

The radiused sanding block gets quite a workout, starting with 80 grit, then moving finer. This is 220 grit. The tiny dimples around the fret slots are filling in with each coat of Diamond Varathane. Ten coats were applied and sanded to radius over a period of nineteen days.

For the final finish process, the next five coats of Diamond Varathane are applied with an airbrush. Here, the Diamond Varathane is thinned slightly with distilled water.

Thanks to my Darling Bride, this stirring moment in history will be preserved forever.

A plastic soda straw makes a nice disposable pipette to transfer the finish to the airbrush reservoir.

We’re loaded. Not much finish is needed for the final coats.

Everything is assembled. This little air brush comes from Harbor Freight, and is surprisingly good quality for cheap ChiCom junk usually found there. The air and the flow of material is easily controlled on the fly, while you spray.

We are experiencing technical difficulties. One moment, please, while we display a Test Pattern.

The sprayed finish goes on much more smoothly than a brushed coat, which is why I switched to the airbrush for the last five coats.

Now this is beginning to look like a fine musical instrument!

The exposed edges of the maple fret veneer is sealed with some Diamond Varathane as well.

For the last two coats, I also sealed the end grain of the fret board.

One coat on the fret board does not require much finish.

The last five coats were wet sanded. Three coats were radius sanded with 400 grit paper, the last two with 1000 grit.

A little rain water was spritzed on the work piece.

Keeping the sandpaper wet is a good way to keep material from building up and clogging the sandpaper.

Wet Sanding At It’s Finest!

Tiny bits of the Diamond Varathane are floated away in the wet sanding process.

Thus begins the final sanding session, 1000 grit wet. Very little material is actually removed. This is just surface prep.

Here is the fret board after the final sanding and dry-off.

This is fifteen coats of Diamond Varathane, rubbed with a cotton cloth to bring out the shine.

Here is a nicer view of the hand-rubbed finish, with reflections courtesy of Mr. Brewster Angle.

Off comes the tape. A tiny bit of wet sanding and rubbing is used to smooth the edge of the finish so that it blends into the original finish on the back of the neck.

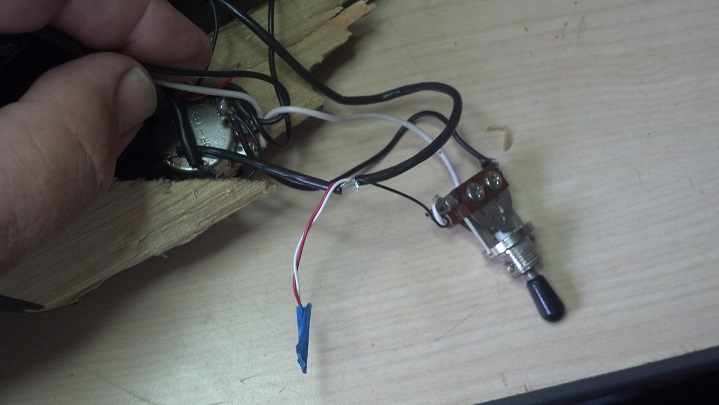

Time for tuners!

Some folks can artificially age guitars with ultraviolet light to remove these ‘tan lines’ but I don’t do that.

Warning – Guitar Porn.

Oops, I need to remove some fingerprints on this side. The nut is glued back on and we’re ready to reattach the neck to the body.

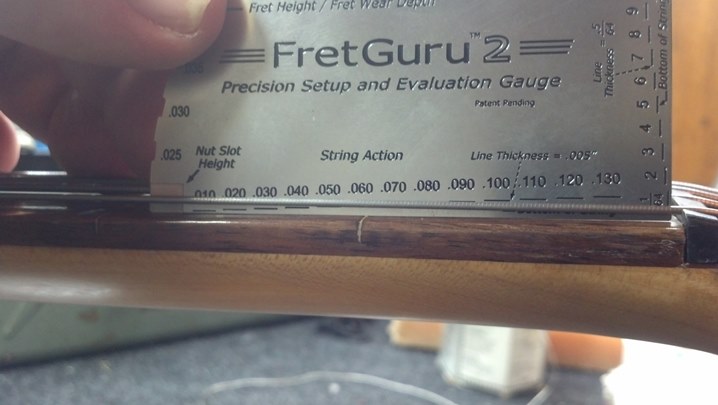

The action is, of course, WAY too high now that the frets are gone.

These strings are about 0.056 inch off the fret board at fret one.

As a sanity check, this gauge shows the same measurement. This is a nice closeup of the finish on the neck. The Diamond Varathane is absolutely rock-hard after curing.

I put this 0.022 inch feeler gauge under the string slots, then proceeded to deepen the slots to just touch the gauge.

Here is the A string file at work.

The plastic nut flows a bit when worked. An Exacto knife trims away the flash.

Time to take any sharp edges off the nut. Playing a fretless bass is all about the “feel,” after all. After a neck shim and a simple setup at the bridge, this bass is ready to mwah.

Thanks for reading all the way to the end of this long post!

CONTACT – David Latchaw EE

281-636-8626