This honest, hard-working powered mixer lives in a music room, where all the musicians can plug in and hone their craft. After all these years, the volume control has become dirty and intermittent. The Unbroken String Crew realizes that this repair will be a wonderful opportunity to show an Old School method for repairing the part, not replacing it.

The unit is a wonderful example of intelligently-packaged, simple product that just works. Four screws, and we’re into this unit.

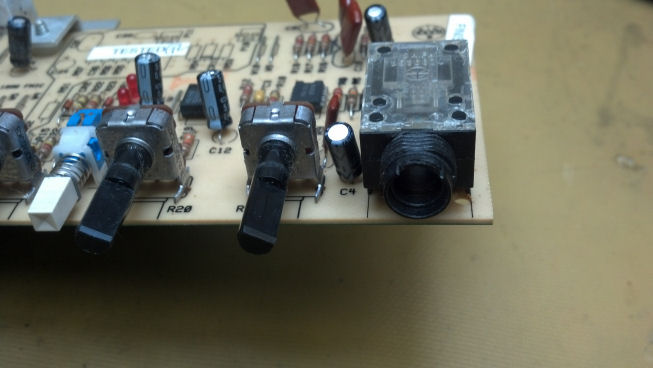

These two circuit boards carry all the front-panel controls and interconnects.

Most of the interior of this unit is empty space. Plenty of room for the reverb pan and power transformer on the bottom. The amplifier is seen on the far side, supported by the rear panel.

The objective today is to clean up the ‘MAIN’ pot, in the lower left hand corner of the big front panel.

The nuts on the front panel controls along with the nuts on the quarter-inch jacks hold the front panel together.

Everything is hand-tightened. A socket and my hand allows enough torque to get the nuts loose.

Here’s what’s behind the front panel. Now the real work begins!

I’ve desoldered the volume control. What I intend to do is to rebuild this control, rather than replace it. By rebuilding this control, we can preserve the original markings, some of which are useful when proving the age and authenticity of guitars and amplifiers.

I’m using a colorful rag to catch all the small parts that always seem to fly away. First, we’re prying open four fingers that hold the back of the control on the body. Yes, I know I shouldn’t use cutters as a pry…

The back of the control is on the left. Inside the control we see the central shaft. On this shaft is a rotor, which is the part that turns with the central shaft. The actual resistor is the dark circle facing the rotor.

We’re looking at two pairs of sliding contacts. The large pair on the left, towards my hand, run on a circular metal contact ring. The overlapping sliding contacts to the right actually touch the resistor itself. These sliding contacts must be clean and dry.

Do not attempt this at home! Leave this to trained professionals! Seriously, a pink eraser is a quick and effective abrasive tool for cutting the crud off the sliding contacts. But we need to be super-careful here because these sliding contacts are very delicate.

The larger sliding contacts touch this circular metal contact ring. The part that I’m holding in my hand is the actual center leg of the control that solders to the circuit board. This ring has a lot of surface oxide and contamination, and is probably why this control was noisy and intermittent.

And here is the circular ring without surface oxide and contamination. We have now begun our path back to a repaired control.

Moving our attention now to the resistor, we see that this ring is actually not too dirty. However, this is very delicate, so we will go slow here and Do No Harm.

All I’m going to do here is lightly burnish the resistor and set it aside. The cotton swab shows what came off the surface of the resistor. I think we’re good here.

Plenty of lubricant remains in this unit. Here, I’m wiping away the surface of the lubricant to remove dust and oxidation. What is under the dust and oxidation is perfectly usable, and will be left in place.

The clean lubricant goes wherever there are moving parts EXCEPT on those sliding contact surfaces. You will recognize that this passage is where the volume control shaft passes through the body of the control.

Everything goes back together where it belongs. I’ll hold this together with one hand while I reach for the pliers.

The four fingers are crimped back into place. This portion of the job is complete.

The control is soldered back into the board where it originally came from. And, yes, my mama told me not to end my sentences in a preposition.

Everything lines back up, including the newly-resoldered control. We’re about done here!

We’re back together. The master volume works perfectly. All the channel strips are good. All Systems Go!

Thanks for reading all the way to the bottom. I hope you have seen enough of the process to gather an understanding of what might be involved in repairing a control versus replacing it with a modern unit. I discussed using vintage parts to repair my Gibson GA-30 amplifier, and made the decision on that project to use modern parts. Likewise, in the previous post about tearing down the Shure 555H microphone, the switch was repaired instead of replaced. So keep the repair process in mind when working on vintage gear that may be dated from EIA codes stamped on controls. Gear may lose value when non-original parts are installed.

Contact Info – David Latchaw EE

281-636-8626