Acoustic is a brand name owned by a national guitar retailer chain. As far as I can tell, they are build in China and very few spare parts are available here in the United States. This bass head was pulled out of a damaged cabinet. The national retailer wouldn’t honor the warranty. The ChiComs just want to sell stuff, not support it. Can the Unbroken String Crew strike a blow for Truth, Justice, and the American Way?

Rather than use an attenuator switch, the user selects an input appropriate for his/her instrument and plugs in here.

Some bass amps separate the gain and volume knob. I really like this setup. The notch is handy for feedback control.

The split mid-frequency EQ is an interesting option, although (spoiler alert!) once I got this amp running and it worked well, I really didn’t get a lot of benefit from this. Maybe you five and six string bass people can weigh in on this feature.

The big blue pilot light was visually interesting and bright. I can’t say it went well with the paint scheme, though.

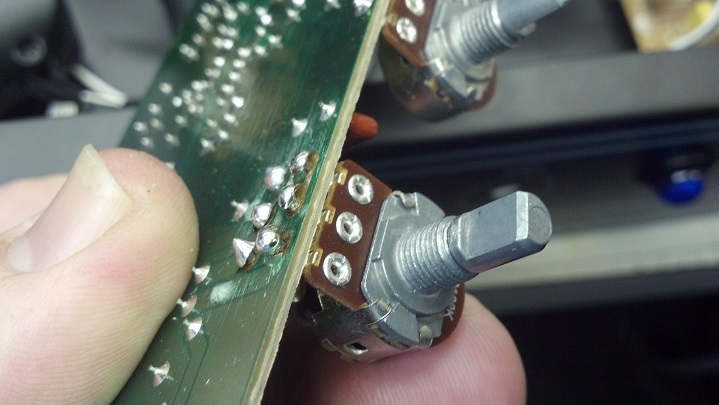

No audio came through the amp. A quick inspection and a little poking around yielded pay dirt! The audio signal always manages to go through the volume control, and, sure enough, the volume control was Ground Zero for the problem. The circuit board underneath the control was somehow intermittent.

No audio came through the amp. A quick inspection and a little poking around yielded pay dirt! The audio signal always manages to go through the volume control, and, sure enough, the volume control was Ground Zero for the problem. The circuit board underneath the control was somehow intermittent.

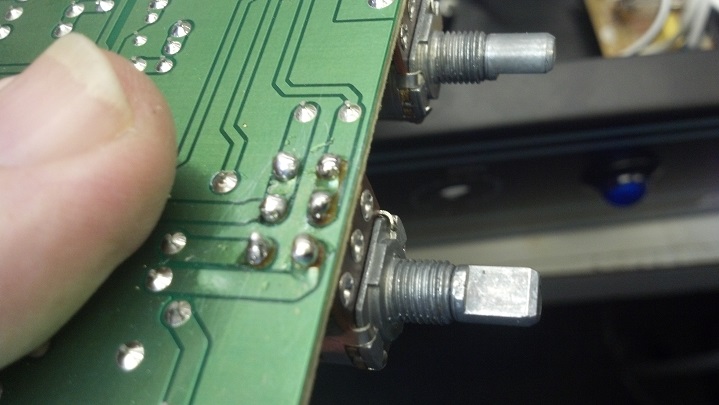

Accessing the underside of the printed circuit board involves removing the front panel circuit board first. Here, I’m using an electric screw driver with a socket attached to finish the job within my lifetime. The face of the socket is covered with felt to protect the face of the amplifier.

The cable to the left takes care of the audio from the front panel preamplifier circuits. The white cable in the center is power and ground.

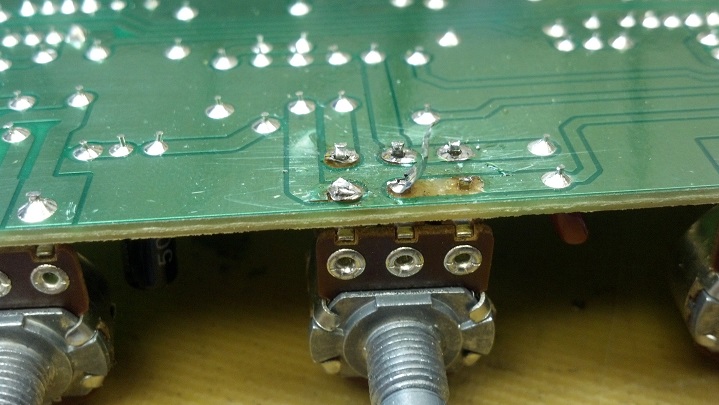

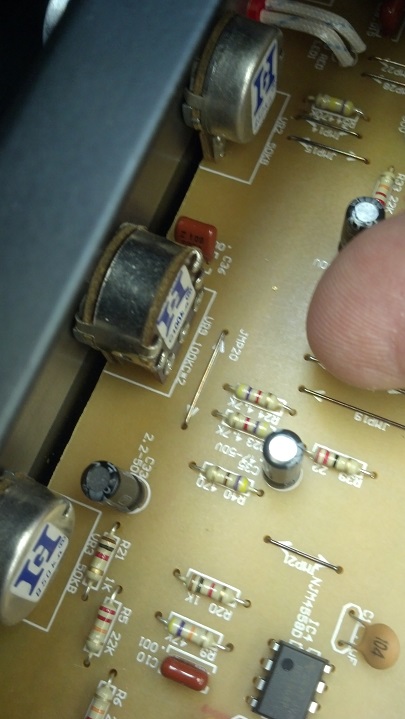

When the amplifier cabinet was damaged, the volume control took the brunt of the shear motion. The circuit board traces separated from the laminate. Thus, our electrical connections were intermittent because the circuit board foil is not very rugged. This is why point-to-point wiring Rules!

The solder is removed, leaving what’s left of the circuit board copper foil exposed. Now copper wire will be routed around all the points in the various nets around the volume control to complete the circuit with something a little more robust than foil.

A little too much solder, which I will go back and fix. But the nets on the board are intact and continuity is good.

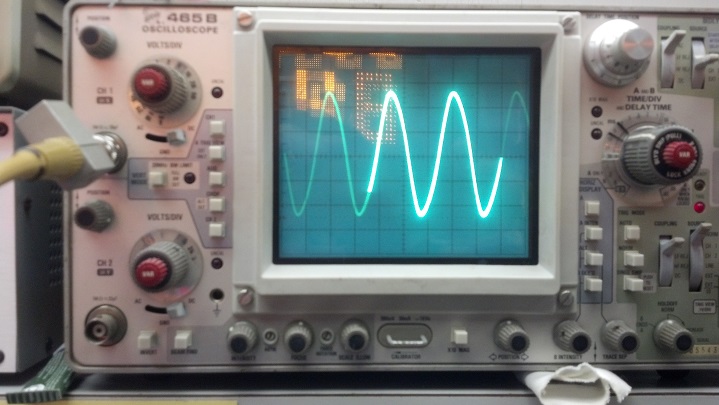

Back together and up on the air! You are looking at 97 watts into 4 ohms at about 41 Hertz.

The Acoustic line is difficult to service because of the dearth of service information. But if someone knows their way around the usual amplifier topologies and can isolate the problem to a specific area, repairs are possible.

Thanks for reading all the way to the bottom!

Contact: David Latchaw EE

281-636-862