Jennifer found this stunning Epiphone Les Paul at a local music store. They didn’t know what they had! Let’s clean it up.

Jennifer found this stunning Epiphone Les Paul at a local music store. They didn’t know what they had! Let’s clean it up.

The only issues I can see are that the pick guard is white but the other parts are ivory. The nut is probably polycarbonate. All the other hardware and pieces appear to be pretty good stuff! Off come the strings.

The only issues I can see are that the pick guard is white but the other parts are ivory. The nut is probably polycarbonate. All the other hardware and pieces appear to be pretty good stuff! Off come the strings.

One of my pet peeves is long, dangly string ends. Why can’t people watch a few YouTube videos and make their guitars a little less dangerous?

One of my pet peeves is long, dangly string ends. Why can’t people watch a few YouTube videos and make their guitars a little less dangerous?

The tail piece is branded Epiphone and is steel.

The tail piece is branded Epiphone and is steel. The bridge is steel as well, also branded Epiphone. String saddles are steel. Everything here is in good shape.

The bridge is steel as well, also branded Epiphone. String saddles are steel. Everything here is in good shape. Jen wanted to remove the pick guard. It didn’t match, and she likes the Studio ethos of a Les Paul sans pick guard.

Jen wanted to remove the pick guard. It didn’t match, and she likes the Studio ethos of a Les Paul sans pick guard. I have been told that this is called a pickguardodectomy. From this view, you can see the mismatch of colors.

I have been told that this is called a pickguardodectomy. From this view, you can see the mismatch of colors. My guess is, this guitar has never been polished since it left the factory. The finish is otherwise in great shape!

My guess is, this guitar has never been polished since it left the factory. The finish is otherwise in great shape! The knobs were not cracked and were not stuck on the pot shafts. The nuts were tight.

The knobs were not cracked and were not stuck on the pot shafts. The nuts were tight. The neck pickup had been screwed way down, but was functional at the music store. Here, I’m temporarily removing it so we can clean up everything.

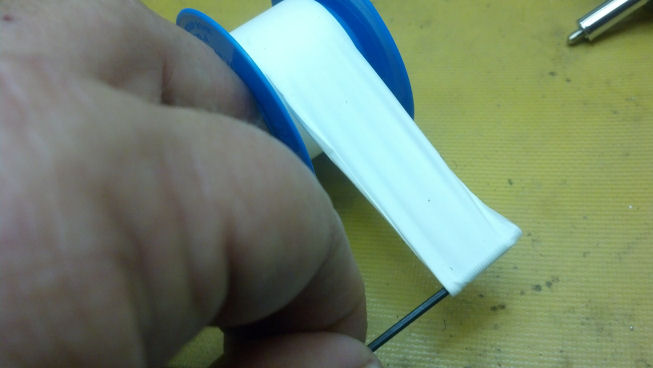

The neck pickup had been screwed way down, but was functional at the music store. Here, I’m temporarily removing it so we can clean up everything. The saddle studs were very loose in their holes, so I bushed up both of them with half-inch Teflon tape.

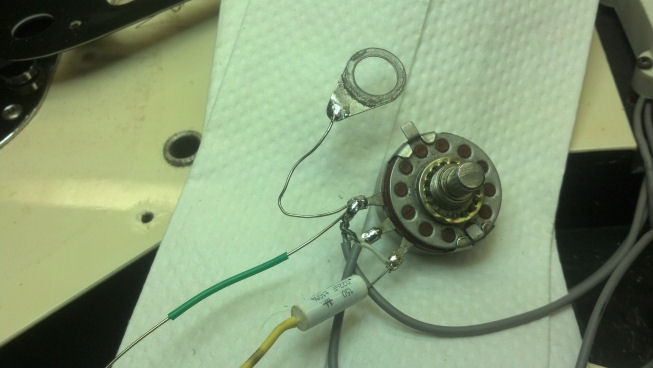

The saddle studs were very loose in their holes, so I bushed up both of them with half-inch Teflon tape. I checked the electronics. Everything was functional at the music store. I removed the covers to remove gunk and better polish the finish. This switch is 100%.

I checked the electronics. Everything was functional at the music store. I removed the covers to remove gunk and better polish the finish. This switch is 100%. The jack is like-new. Again, I removed the cover to better polish the finish. Note the more-than-adequate service loop. I wish more guitar companies did this, but, alas, copper wire costs money. Thus, you can always be assured that you won’t get any more than necessary. But this Epiphone is a welcome change from the norm.

The jack is like-new. Again, I removed the cover to better polish the finish. Note the more-than-adequate service loop. I wish more guitar companies did this, but, alas, copper wire costs money. Thus, you can always be assured that you won’t get any more than necessary. But this Epiphone is a welcome change from the norm. The bushings on the top side of the tuners were not even finger tight. I’ll take this opportunity to pull off the hardware and polish the headstock.

The bushings on the top side of the tuners were not even finger tight. I’ll take this opportunity to pull off the hardware and polish the headstock. The entire neck is finished. Here are some cryptic marks on masking tape for you to decipher.

The entire neck is finished. Here are some cryptic marks on masking tape for you to decipher. True to the Les Paul formula, this body appears to be mahogany with a maple top.

True to the Les Paul formula, this body appears to be mahogany with a maple top. After I installed the neck, I noticed that the badge on the headstock appears to be an inlay, perhaps synthetic abalone.

After I installed the neck, I noticed that the badge on the headstock appears to be an inlay, perhaps synthetic abalone. The front of the body is done and is ready for strings. The neck got the usual fret polish and cleaning. The fret board was filthy, taking three applications of Dr. Duck’s to bring it back to life.

The front of the body is done and is ready for strings. The neck got the usual fret polish and cleaning. The fret board was filthy, taking three applications of Dr. Duck’s to bring it back to life. The back is absolutely perfect, no buckle rash or any signs of chips or damage.

The back is absolutely perfect, no buckle rash or any signs of chips or damage. Strung, tuned, truss-rodded, string-heighted, intonated, played. Jen found a real winner here!

Strung, tuned, truss-rodded, string-heighted, intonated, played. Jen found a real winner here! Welcome to the Les Paul Zone!

Welcome to the Les Paul Zone!