Broken input jacks are a pain in the “ear.” The replacement of switches and jacks is the bread-and-butter for the bench technician. Let’s see if the Unbrokenstring Crew can take this otherwise-mundane repair to the next level!

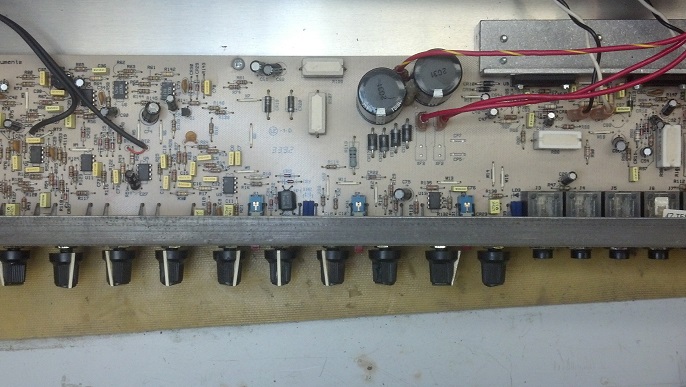

Looking inside, we see a big toroidal power transformer on the right, a power supply unit in the center, and a big heat sink with cooling fan on the left. These are the main components in a Class D (switching) power amplifier. Tone-shaping and low-level audio tasks are performed on the circuit board behind the front panel and around the periphery of the main circuit board.

At this angle, we can see that our objective is to get the long blue circuit board behind the front panel out of the chassis where we can replace the input jack. The power switch is the silver box to the right and is not part of the blue circuit board. It comes out first.

We turned the chassis around and went searching for a screw driver that was ‘just right’ to properly fit the Phillips-head screws and with a handle to supply enough torque to do the job while allowing us some space over the power transformer.

Now, all the knobs come off. All of them. Two screws holding the face of the three-pin XLR jack come out, too. With the hardware completely out of the way, we will have an opportunity to easily clean up the front panel.

If you look closely at the jack in the middle of the picture, you can see that it is cracked.

I am not EVEN going to ask what happened to the effects in/out jacks. Houston is a humid climate, but humidity and mold did not cause this! Not to worry… we’ll change these out too as they are the same part as the input jack.

The blue corrosion is copper sulfate. This is commonly seen around copper that has been exposed to the out-of-doors, or perhaps in this situation, the not-quite-out-of-beers. Note the D15 and D16 LEDs on the right. More on these later!

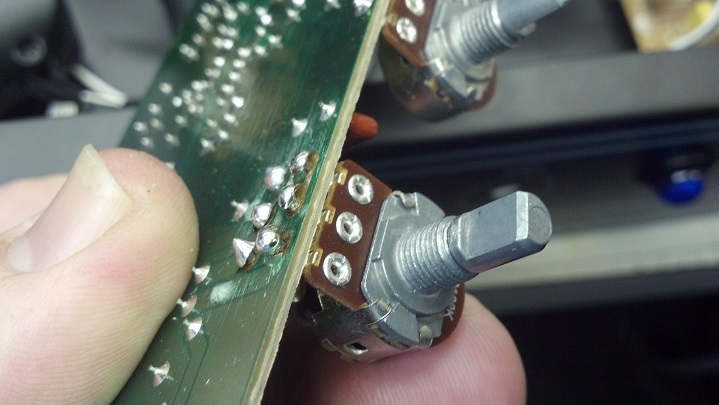

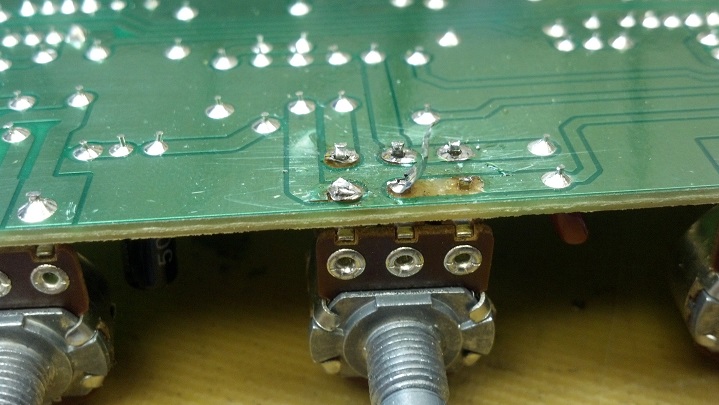

The owner mentioned that he had sent the amp back to GK for an input jack replacement. I’m not impressed with their workmanship. The brown gunk is solder flux. Usually, solder flux is not conductive, but the dust and moisture it attracts is. And, as you can see, the input jack finished breaking. The threaded part fell off and is somewhere on the floor now.

Here is the carcass of the old input jack, free from the circuit board. The circuit board has been cleaned up with alcohol and wiped clean.

OK boys and girls, listen up all you GK Amp repair persons. This post will save you money and increase your profits. Two new jacks lie on either side of the original (broken) GK input jack. The ‘factory’ GK jacks are available online for prices that range between $5 and $13 each. The ‘factory’ jack is identical to the Amphenol part seen on the left. I will leave it as an exercise for the graduate student to write down the Amphenol part number and the Mouser part number that are printed on the label on the left. As an added bonus, the jack on the right is identical to the GK input jack except it has a small metal tang that is intended to make electrical contact with a metal front panel. If you look closely at the jack on the right, you will see this tang. This is just an FYI… you want the jack on the left for most GK applications. Did I mention that the full retail price for this jack, in single quantities, plus Texas sales tax, is less than one dollar?

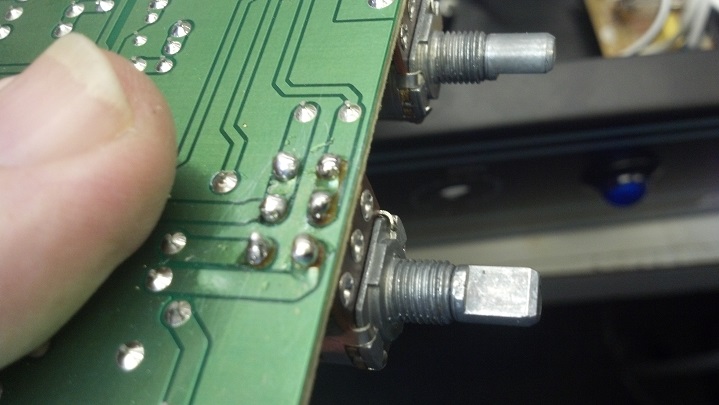

Here’s the New Jack City being soldered in. We’ve now begun the reassembly process.

The effects jacks were also removed and the circuit boards cleaned up. Here you can see some pesky copper sulfate remaining to be cleared out. Whatever the contaminate was, it was water-soluble as it wicked under the blue solder mask on the circuit board. No beer I’d drink…

The less-than-one-dollar Amphenol jack comes with nicer hardware than the factory GK jacks. Here, you will see a nice hard rubber washer behind the beefier nut. The rubber washer doubles as a shock-absorber and a lock washer. The original GK jacks had no washer at all, but rather, a flat washer was molded into the base of the nut. The new nuts are tightened finger-tight e.g. as tight as you can get them without using tools.

Again, really a nicer jack. And, did I mention that these were under a dollar, full retail price?

This is another picture of the XLR jack, with the mounting screws. Have you spotted the clean front panel?

Knobs. Lots of knobs. And they all go back on in a particular orientation. More knobs…

Everything is back together, including the rack ears.

Last pic. Here are the new effects loop jacks, and the neat power indicator. If you check out the earlier picture of the blue corrosion on these jacks, you will see two LEDs stacked one behind the other on the circuit board. This is an easy way to make a multi-color indicator. When the power comes on, the LED is red. Then when the power is stable, the indicator switches to blue. Very cool-looking! This is the only way, in my experience, to build a multi-color indicator that includes blue with common colors.

Thanks for reading all the way to the bottom of the post!

CONTACT INFORMATION – David Latchaw EE

281-636-8626 voice or text

This unit was actually made in the USA, and the city of Los Angeles has duplicated the work of UL/CSA, for a fee, of course. Is this a great country or what? Let’s get to work!

This unit was actually made in the USA, and the city of Los Angeles has duplicated the work of UL/CSA, for a fee, of course. Is this a great country or what? Let’s get to work! Separate cable pairs come out of the chassis for each loudspeaker. Nobody has touched this in a while!

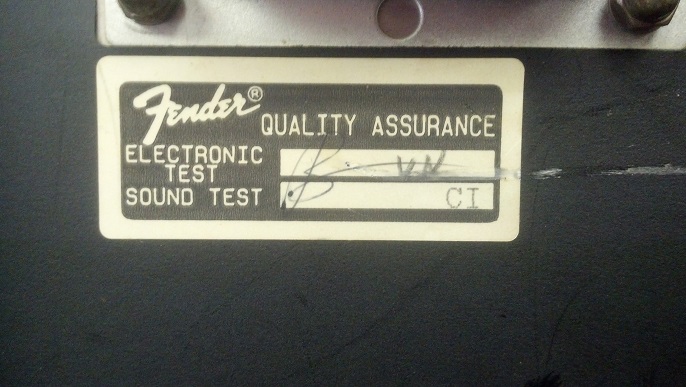

Separate cable pairs come out of the chassis for each loudspeaker. Nobody has touched this in a while! Today’s mission objective is to fix this. You can read my earlier rants about plastic input jacks and international safety approvals. But, to keep this amp original, we will go back with the authentic Fender part.

Today’s mission objective is to fix this. You can read my earlier rants about plastic input jacks and international safety approvals. But, to keep this amp original, we will go back with the authentic Fender part. Here’s the amp on the bench. WARNING: Tech Porn To Follow

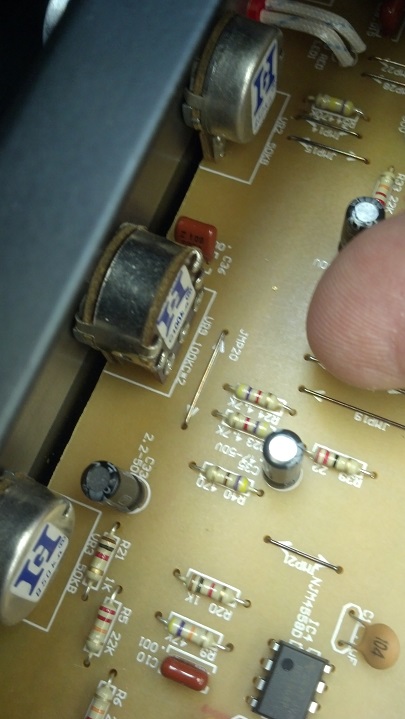

Here’s the amp on the bench. WARNING: Tech Porn To Follow This top view shows the usual single-sided circuit board found in a lot of consumer gear. This amp is pretty clean inside!

This top view shows the usual single-sided circuit board found in a lot of consumer gear. This amp is pretty clean inside! Some folks have asked about the felt-covered sockets I use. Here is a closer picture of the one I will use on this faceplate. The faces of a set of sockets is ground flat on a bench grinder. A square scrap of felt from the fabric department is super-glued to the ground face. When the glue is dry, an Exacto knife liberates any felt that is not glued to the socket itself.

Some folks have asked about the felt-covered sockets I use. Here is a closer picture of the one I will use on this faceplate. The faces of a set of sockets is ground flat on a bench grinder. A square scrap of felt from the fabric department is super-glued to the ground face. When the glue is dry, an Exacto knife liberates any felt that is not glued to the socket itself. A little automation goes a long way. This little low-rpm driver keeps the carpal tunnel problems away.

A little automation goes a long way. This little low-rpm driver keeps the carpal tunnel problems away. Compare the old jack on the left with the new jack on the right.

Compare the old jack on the left with the new jack on the right. The reassembly is the reverse of the assembly. Another happy customer picks up his amp!

The reassembly is the reverse of the assembly. Another happy customer picks up his amp!