What have we here? A road case for The Deer Hunter? Or perhaps a Big Buck Body Bag? Let’s See!

Zach says his amp plays like crazy but one tube will red-plate. The high voltage place power supply fuse will blow. This cannot continue. Can the Unbrokenstring Crew help?

Awesome dinosaur visuals dominate the Plexiglas window, and the Tolex deserves a closer look. Wow!

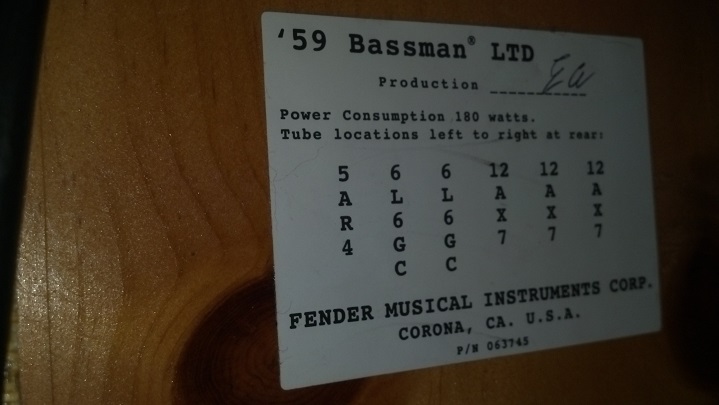

Five preamp tubes handle preamp duties on two input channels, driving two pairs of 6L6 tubes that can be split for half-power operation. No rectifier tube in sight, so I assume solid state rectifiers live under the chassis. I really like the beefy switches used for selecting the input voltage and setting the loudspeaker impedance.

This Tolex covering makes me drool like a noob. Just stare at it for a while. I am already dreaming up future projects that I will start just so I can cover them with this stuff. Yes, I know where to buy it in quantity.

This light show drew a lot of attention around the office. The Plexiglas is etched on the back side. Red LED light shines invisibly through the clear Plexiglas but scatters toward the observer’s eye when it hits the etched pattern. A small green LED makes a feeble attempt to illuminate the tubes. Extra Credit For You if you can see it.

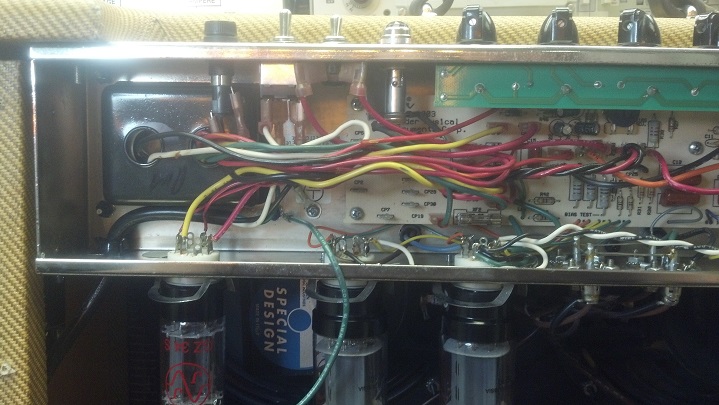

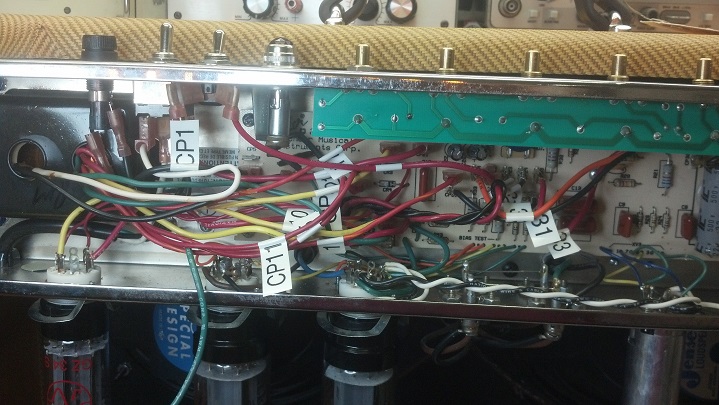

A confirmed NO AUDIO condition launches some exploratory surgery. Based on the red plate report, we should look around inside before burning up any more tubes. This unit uses commercially-available parts throughout; the sticker for the output transformer lives on the chassis near the transformer itself.

Along the same lines, AC power conversion is handled by this off-the-shelf transformer. I really like how Moss has done this ‘build.’

A fresh fuse of the proper ratings now lives in this fuse holder. If you ever do this yourself, BE AWARE that voltages and currents at this point are LETHAL, even with the power cord unplugged. This fuse is not considered a user-serviceable component for this reason.

The high voltage rectifiers and filters are on the upper eyelet board. Low voltage DC is rectified so that the preamp tube filaments are always fed direct current. A 5v power source for LEDs and control switching is found on the lower eyelet board.

The circuitry for the preamp tubes are to be found on the lower center eyelet board. If I had done this amp, I don’t know that I would have done a thing differently! Well done, Mr. Gelinas!

Can you say that you have made something that you were proud to sign you name to it?

We’re up and running with a set of shop spares fulfilling the role of output tubes. During the second day’s test run, power consumption increased slightly, then things started happening quickly. I shut the amp off as the third tube from the left began to get hotter than usual. I did some circuit checks, then restarted the test. Later, the same thing happened again. I moved tubes, no difference. But the problem didn’t happen every time. Turns out, I had a parasitic oscillation that occurred only in tube 3. Sorry, no oscilloscope pics, but they come later.

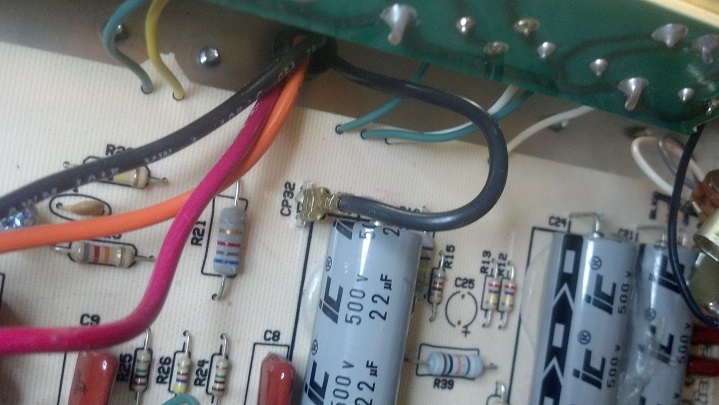

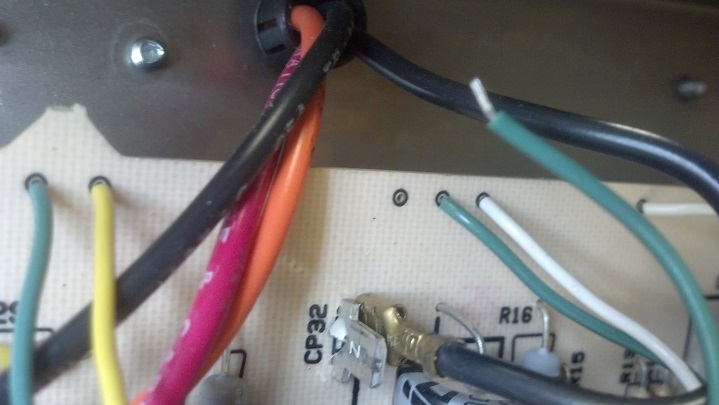

Parasitic oscillations may occur whenever energy storage components (capacitors, inductors) are used in gain circuits. Parasitic oscillations are rare in audio circuitry, but can happen. The inductor hidden in this picture is in the form of the wire wound cathode bias resistors, seen here as those white rectangular items in this picture. These happen to be made by Xicon, the inexpensive Chinese house brand carried by Mouser Electronics.

The white Xicon resistors have been removed and replaced with these non-inductive wire wound resistors of the same resistive value and wattage.

These resistors also came from Mouser, and just cost a few cents more than the Xicons that are now in the bottom of my trash can.

Now that I have some confidence that we have a handle on the root cause, we’re installing a fresh set of JJ Tesla 6L6 which is what Moss used when they built these amps. And I have a local dealer.

This is my favorite part of the job! It’s beginning to feel a lot like Rock and Roll Time.

This is what 100 watts into a non-inductive eight ohm solid state load looks like with a 440 Hz (concert A) sine wave running through the clean channel into four paired push-pull 6L6 tubes. No fans were used to conduct this test. The Moss amp is conservatively engineered and can do this all day long.

Now for some bling. These high-intensity white LEDs are super-glued into these brackets. I wonder if this amp was a prototype? I didn’t ding up these brackets getting them out. They came that way.

To add some real intensity to that anemic internal illumination LED, this is a high-intensity blue LED I ordered for the occasion.

The aluminum bracket makes an excellent heat sink for the new high intensity LED. I just used heat shrink tubing to keep it in place and to insulate it electrically where the wiring is attached. The red connectors are male/female spade connector pairs that replaced the original ‘low-boy trailer light’ connectors Moss used, which I replaced because they were becoming intermittent.

Betcha’ can see this LED now!

LEDs check out.

In order to increase the current to the values needed by the white and blue LEDs, small appropriately-rated resistors were placed in parallel to the original LED bias resistors. Remember that the value of two resistors in parallel is equal to the reciprocal of the reciprocal of their sums.

Wood screws hold the edge light LEDs in place, so that the LEDs shine into the Plexiglas.

A little black paint touches up everything so it appears that no one was here. All wiring is new, with black insulation.

This is the finished product. The blue light is really working for us to show off the interior, and the white illumination of the engraving is just what Zach wanted. This works better with his white Tolex cabs.

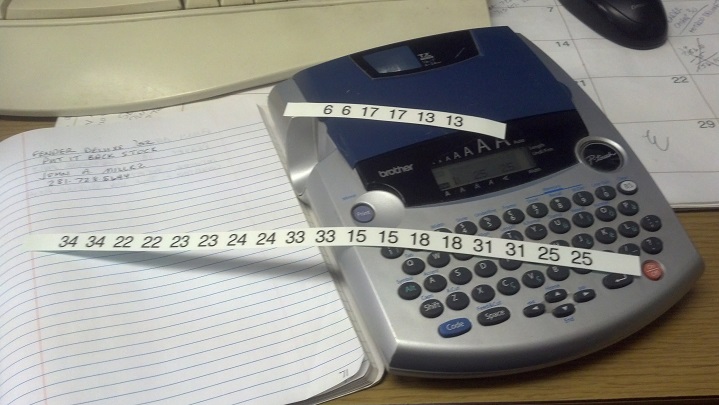

Zach moved to Knoxville TN before the amp was ready, so I’m shipping it to him in two boxes. One box holds the head in the case and the other box has all the breakable glass in it.

Here’s the glass. Most of this box will be bubble pack.

This is the box of tubes. Time for a cup of coffee, and another larger box to protect the glass!

Most ATA flight cases have foam, but this head case had none. I’ll make do with bubble pack.

Good practice for Christmas! This is the only pic I have of the rear cover panel installed.

And now we have gone full-circle, to the Big Buck again. One more step!

Jen is holding the shippable box containing the glassware, and the case with the amp head is in the larger box. Off to Knoxville where Zach has gigs and a contract waiting for him. Best of luck to everyone!!

Thanks for reading all the way to the bottom!

David Latchaw, EE

281-636-8626