This stereo rack mount effects processor had a couple of problems. When turned on, the display would flash. And the rotary encoder is busted. And we really need to get this fixed this week. And many parts are obsolete. Can it be fixed in time? The Unbrokenstring Crew to the rescue!

These units are, in my opinion, highly-under-rated. When they work, they sport an innumerable list of effects. When they don’t work, they are still prized for spare parts.

This unit needed a new rotary encoder. If there is one mechanical design problem, you are looking at it. This big knob sticks out farther than anything else on the front panel, and therefore takes a beating if the unit is abused. And, of course, this exact part is not available anymore. Let’s open up the unit and go to work!

A firmware upgrade kit is still available from an eBay vendor, that adds delay time and new effect algorithms. The new parts go here. This unit will not be upgraded at this time, but if you are considering the upgrade, it’s not difficult at all.

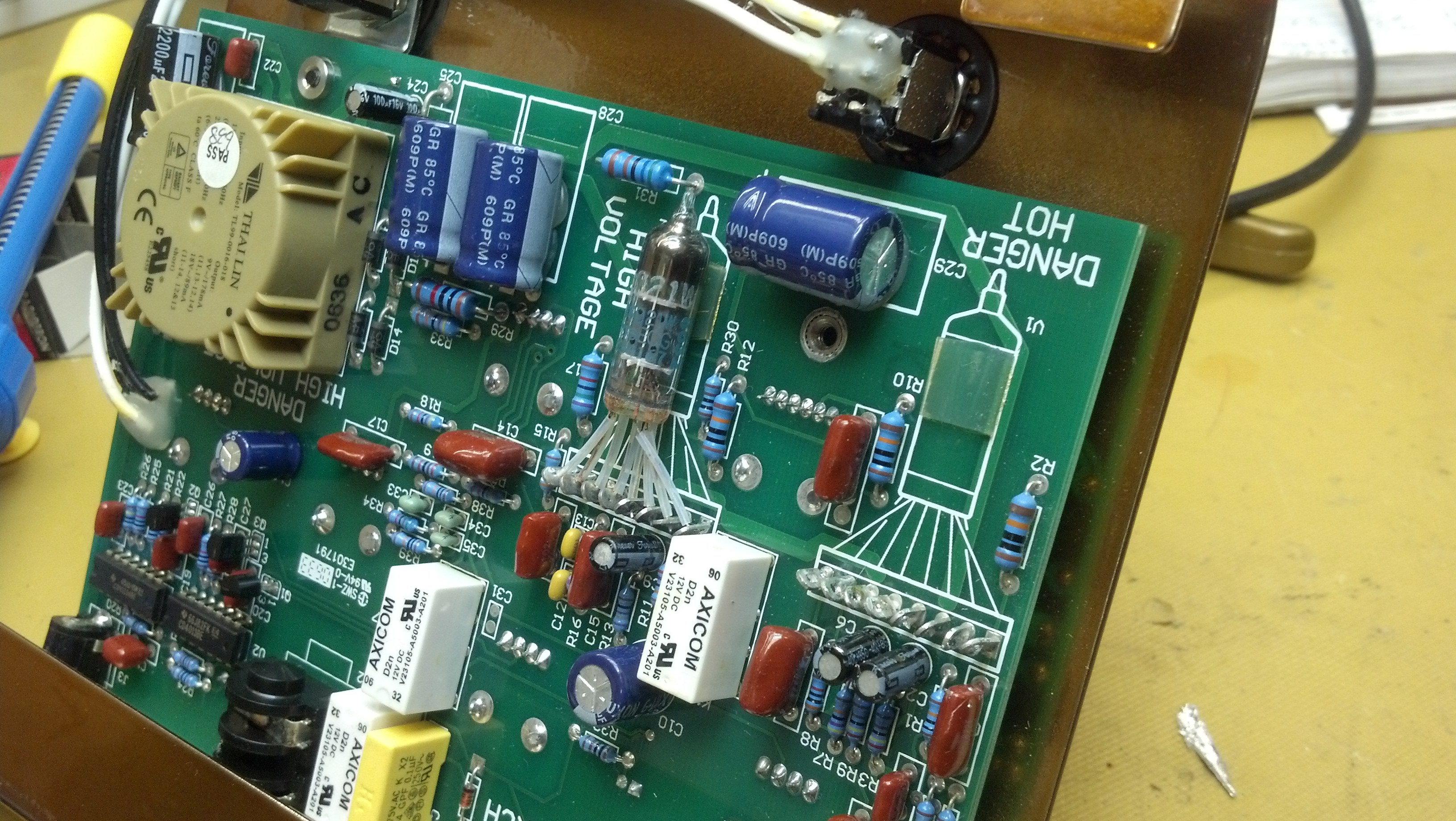

More tech porn. This is a custom processor flanked with other members of the DSP chipset.

We need to remove the circuit board entirely from the chassis in order to replace the failing voltage regulator. These nuts and washers all come off. Fortunately, they are finger-tight.

Interestingly, the screws holding the front panel in place are Allen head cap screws. They look very cool.

More Allen head cap screws secure the external heat sink. The voltage regulators are behind this heat sink.

Just documenting where all the cables go.

The configuration of the wiring harness determines if the particular unit is 115vac or 230vac. No switches or jumpers!

This pin was loose in the circuit board. We’ll repair this solder joint when we get the board out.

OK, I think I got it out.

The voltage regulators are inside this sandwich of aluminum channel. The big heat sink seen in a previous picture bolts behind the aluminum angle bracket, seen at the top of this photo.

With the top piece of aluminum channel gone, the voltage regulators are easily accessible. DigiTech used a grey silicone pad underneath the regulators instead of messy grease.

The new regulator is soldered in from this side. Can you tell that the three joints to the right are ‘shinier’ than the others?

The aluminum sandwich goes back together.

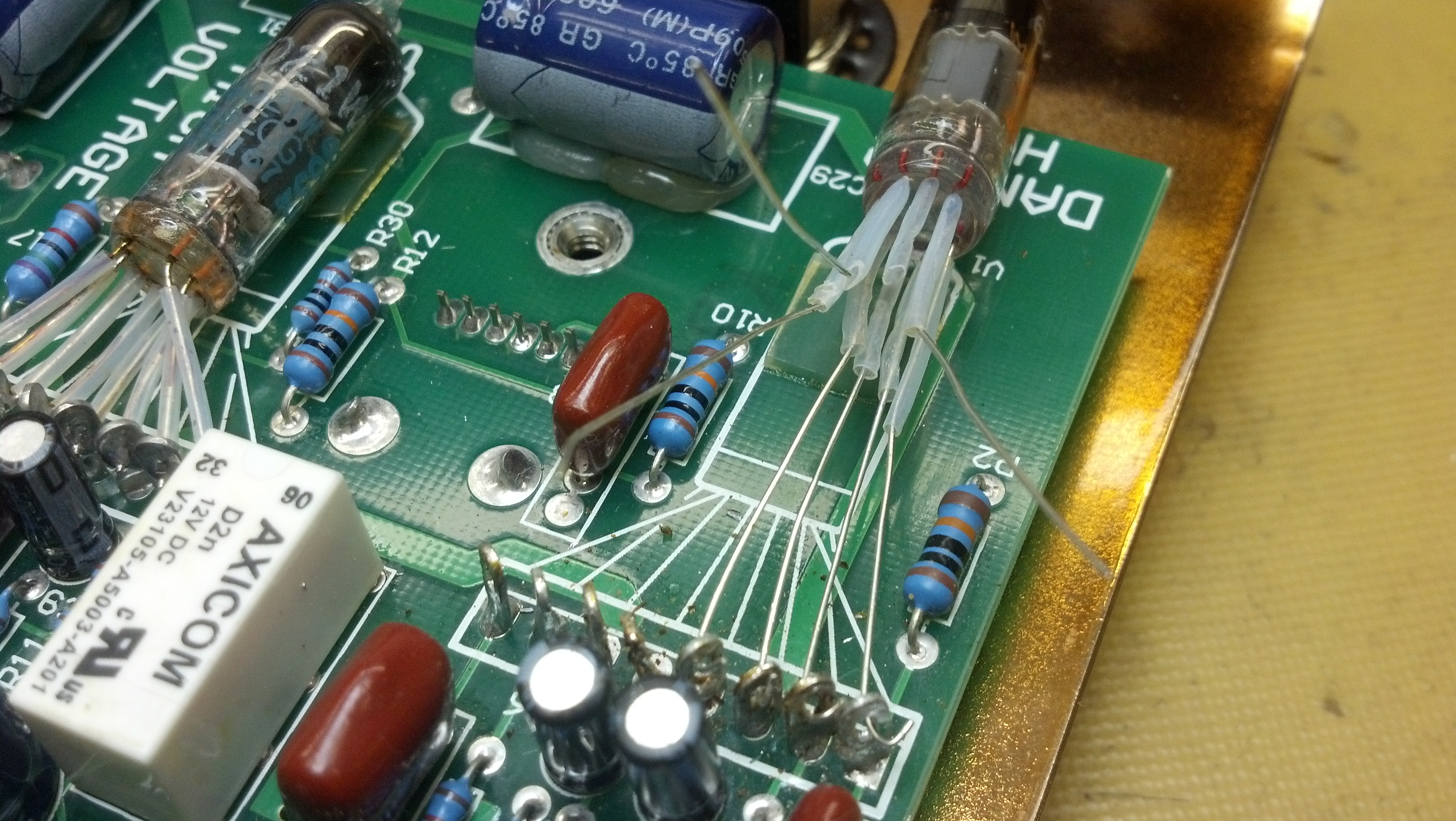

Now that the mechanical sandwich is secure, I am reflowing the solder joints to remove all mechanical stresses.

The loose pin seen earlier was not the only issue. Two pins fell out of their holes!

The solder joints beneath pins at Q11 and Q12 were re-flowed with rosin solder. The flux seen here will clean up with isopropyl alcohol.

This sub-assembly, called the “Pot Board,” carries the rotary encoder, the control with the white shaft seen in this pic.

That’s the problem! Of course, this part is no longer available.

Here is a better look at the damage. When the knob is banged inward, the phenolic circuit board used to implement the rotary encoder takes most of the stress.

Let’s clean up this mess. No sense in leaving the broken pieces in the unit!

I prefer braid and rosin to clear out plated thru holes in circuit boards.

The plan will be to transplant the white nylon shaft and bushing into the new encoder body.

The new rotary encoder was dis-assembled. The old shaft assembly is on the left, and will mate directly with the circuit board. Note that this rotary encoder has a different land pattern than the original. This circuit board will make fewer pulses per revolution. In my opinion, slowing down the action of the knob is a Good Thing on this unit.

Here’s the completed “V’Ger” rotary switch. The tabs on the back hold everything together, assimilating the two encoders; a tip of the hat to the Star Trek movie when the Voyager space probe ‘merged’ with an alien probe, then returned to Earth to ask the question, “Who’s my daddy?”

Here is a good view showing how everything lines up.

The new encoder board has a slightly wider pin spacing, but nothing that will keep us from finishing this project.

Here is the pot board assembly with the new encoder assembly installed.

That pot board assembly shoe-horns behind the front panel. All the electrical connections are made thru the ribbon cable. The cable needs to be mated first before the pot board is installed, because it won’t mate after the board is installed. Don’t ask me how I know that…

Now everything fits. This is a good view of the little bit of gun-smithing necessary to get the new encoder board onto the site on the pot board where the old one was located. We’re on the home stretch!

Re-using the original shaft and bushing allows us to stay with the original knob and hardware.

The instructions to perform a factory reset are freely available online and in the manual.

All done! No flashing display, and the rotary encoder knob steps through all 255 different banks of effects at a sane rate. This unit is ready for another decade of duties around the studio.

Thanks for reading all the way to the end!

CONTACT – David Latchaw EE

cell – 281-636-8626