One of my repeat customers cruises the pawn shops and from time to time picks up interesting-looking items.

He called me to tell me that he had gone shopping again and to bring the truck this time!. He had another project for the Unbroken String Crew to refurbish!

This unit had sustained some damage to the input jacks, perhaps from falling over. Only one of the jacks would accept a quarter-inch plug.

The original wiring scheme allowed for this cabinet to be daisy-chained with another loudspeaker cabinet. My customer had something else in mind, to make this into a stereo cabinet. Off we go!

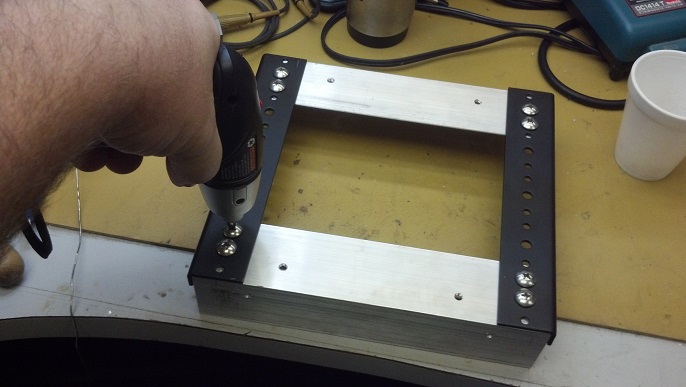

I am unsoldering these two jacks to separate them and make them independent. One of the jacks had been deformed, so the sleeve was refurbished using a reamer to lightly remove a lip over the hole.

Now the jacks are reinstalled, but rotated so that the internal contacts don’t touch each other.

The original loudspeakers were dry-rotted, and two of the voice coils dragged on the magnets. Time for an upgrade!

“FST” stands for Formosa Speaker Technology in, as you might not expect, Mainland China. They have a one-inch voice coil. These were probably OK when not driven too hard when they were new, but they have deteriorated over the years.

These little jumpers connected everything together. I would guess these are about 22AWG wire gauge. I will go back in with red and black 16AWG that I have on-hand. A bit of overkill, but there will be no question about the wire getting in the way of voice coil current when using the larger wire.

My customer asked for a stereo cabinet, with the loudspeakers in each channel wired on the diagonal as shown here. I can use the old loudspeakers as a mock-up to build the new wiring harness.

With all the loudspeakers in place, this will be the approximate wiring setup. My customer has a stereo guitar amplifier with which to drive this cabinet. The loudspeakers in the guitar amp were sixteen ohm units in each channel. To limit the load on each amp channel, this cabinet will be wired so that these loudspeakers are in series and the total load of each channel will be 16 ohms. When this cabinet was plugged into his stereo guitar amplifier, the amp will then see an eight ohm load per channel.

This clip lead allows a pair of wires to be snaked around inside the enclosure.

Four of these guys arrived from eBay. They were pulls from another project in favor of Greenbacks, but these loudspeakers will be just fine for what we’re doing.

I pulled the new 16AWG wiring into the cabinet and began installing loudspeakers.

A quick check of polarity and phasing reveals that all is OK with the assembly. Time for all the screws to go in!

A straight application of Pledge furniture polish and a toothbrush is cutting years of crud out of the Tolex. A little furniture polish will leave the cabinet “Lemon Clean”, as the ad says…

The last picture should show the completed system, but I think this picture, taken before the original grille is reinstalled, is better!

Thanks for reading all the way to the end of this post!

CONTACT INFORMATION : David Latchaw EE

281-636-8626