The owner of this amp was so anxious to get it fixed, he removed the chassis from this Peavey Stereo Chorus 212 combo and even helped load it! The amp plays, but only one stereo channel is operational. Can the Unbrokenstring Crew help?

A quick look of the front panel shows the inputs and the normal (clean) channel controls.

A quick look of the front panel shows the inputs and the normal (clean) channel controls.

Did you catch the missing knob? The Unbrokenstring Crew will find a replacement, which is no small thing because these are no longer available new and are only available from spares or salvaged from a non-working unit.

Did you catch the missing knob? The Unbrokenstring Crew will find a replacement, which is no small thing because these are no longer available new and are only available from spares or salvaged from a non-working unit.

This amp uses a digital signal processing (DSP) module to make all this audio magic.

This amp uses a digital signal processing (DSP) module to make all this audio magic.

Interestingly, the DSP module creates two unique audio signals (stereo) from a single mono input.

Interestingly, the DSP module creates two unique audio signals (stereo) from a single mono input.

The ground lift switch is on the front panel, which is a nice touch from many other designs.

The ground lift switch is on the front panel, which is a nice touch from many other designs.

This dual OPAMP is non-functional. However, this is not the root cause of the missing stereo signal.

This dual OPAMP is non-functional. However, this is not the root cause of the missing stereo signal.

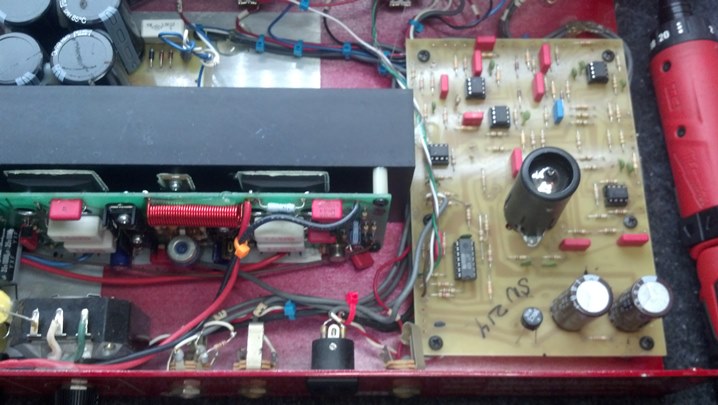

This is the DSP module in this amplifier. We have only one audio stream as an output from this device.

This is the DSP module in this amplifier. We have only one audio stream as an output from this device.

A piece of cardboard serves an an insulator so that the bottom of the DSP assembly can be probed.

A piece of cardboard serves an an insulator so that the bottom of the DSP assembly can be probed.

Here is where the DSP processor outputs both audio as a stream of ONEs and ZEROs. We are OK here!

Here is where the DSP processor outputs both audio as a stream of ONEs and ZEROs. We are OK here!

This chip processes the two DSP streams in a manner similar to a successive approximation analog-to-digital converter.

This chip processes the two DSP streams in a manner similar to a successive approximation analog-to-digital converter.

The bit streams are split using an analog switch. Here is the output of the switch assigned to the working channel.

The bit streams are split using an analog switch. Here is the output of the switch assigned to the working channel.

And this is the output of the switch on the non-working channel. Time to change the switch!

And this is the output of the switch on the non-working channel. Time to change the switch!

Desoldering today is performed with a traditional iron, rosin flux, and copper braid. This keeps solder balls to a minimum.

Desoldering today is performed with a traditional iron, rosin flux, and copper braid. This keeps solder balls to a minimum.

The circuit board is cleared of excess solder and flux.

The circuit board is cleared of excess solder and flux.

The new MUX chip is available through the usual sources.

The new MUX chip is available through the usual sources.

With the tweezers, the new MUX chip is oriented properly on the circuit board pads. See the tweezers?

With the tweezers, the new MUX chip is oriented properly on the circuit board pads. See the tweezers?

After soldering, the workmanship is inspected with this hand-held microscope. The high-powered white illuminator is on the left, and the black cylinder next to the big IC chips is the optical microscope itself.

After soldering, the workmanship is inspected with this hand-held microscope. The high-powered white illuminator is on the left, and the black cylinder next to the big IC chips is the optical microscope itself.

Any remaining solder flux is removed with alcohol. The rag gives the dissolved mess somewhere to go.

Any remaining solder flux is removed with alcohol. The rag gives the dissolved mess somewhere to go.

Both channels are operating at full power. The knob is coming from an eBay auction. When it gets here this head is ready to return to the eager customer!

Both channels are operating at full power. The knob is coming from an eBay auction. When it gets here this head is ready to return to the eager customer!

Thanks for reading all the way to the end!

CONTACT – David Latchaw EE

281-636-8626