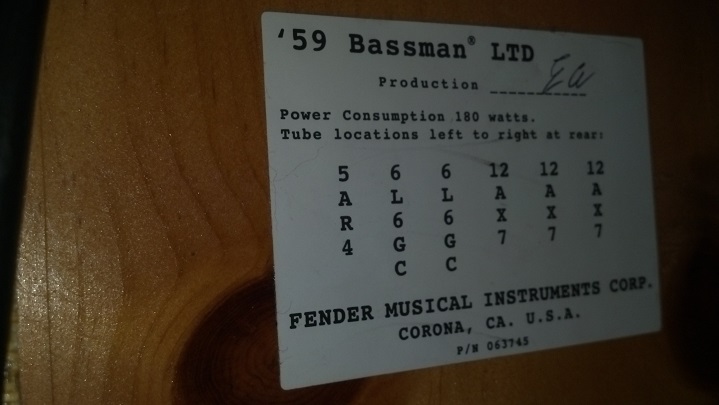

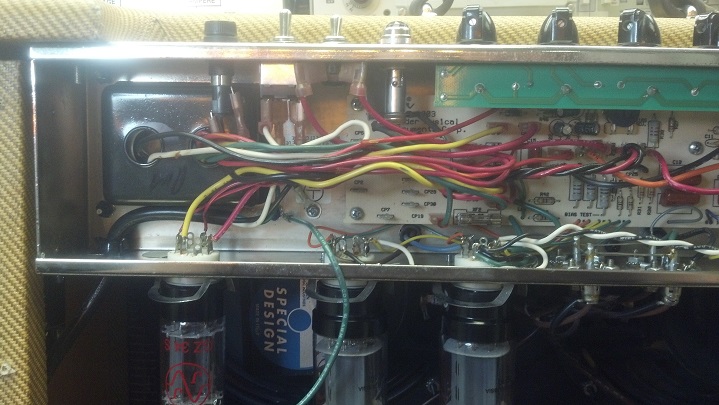

An interesting tool came in the mail from the good folks at Grizzly Tools. This file is polished smooth, with two quarter-round concave file surfaces on opposing corners. It can be used as an alternative to the traditional fret dressing file. Let’s try it out on my 1968 Gibson C-0 classical guitar, that was cleaned up in an earlier post but could still benefit from a thorough fret dressing. (Photo courtesy of Stewart McDonald.)

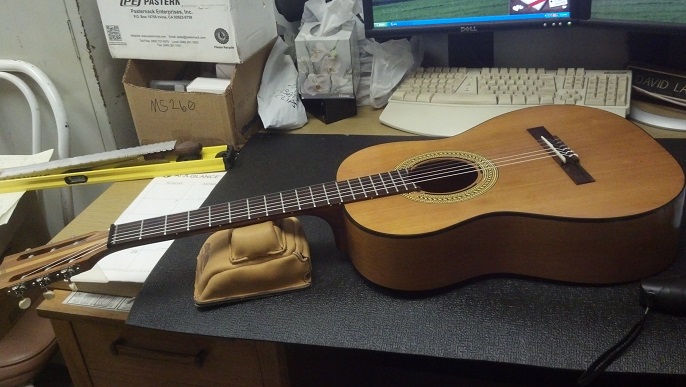

I’ve recently added a leather sandbag to my luthiere tool set. The little bunny ears really hold the neck securely. NOTE: Be Aware that this bag is sold as a rest for use at the gun range, but makes an awesome neck support.

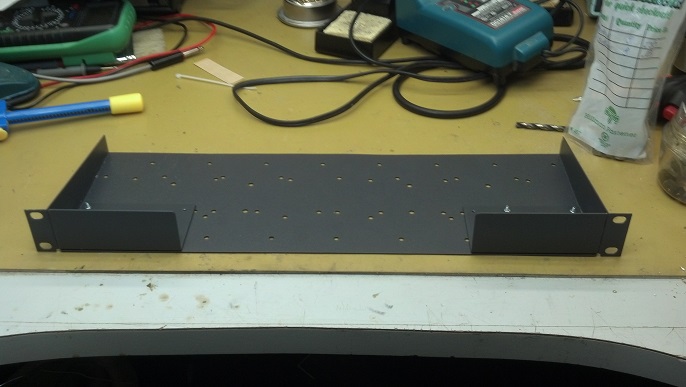

The mat is a section of a floor covering used in gyms. These mats are often used underneath workout machines and in the free weight areas. They are tough and plenty cushy, just the thing for your luthier’s workbench. And one mat can be slit into enough pieces to outfit four or five guitar workstations.

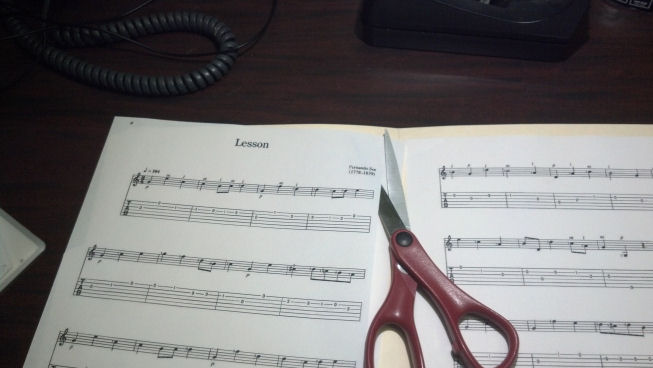

I covered the sound board with a sheet of corrugated cardboard. No sense in risking any damage to that fifty-year-old piece of cedar! A pair of heavy-duty scissors is barely adequate for the job.

So here’s the cardboard sound board cover at work. This will keep stuff out of the sound hole as well as help prevent gouging the guitar.

The frets are leveled with emery paper glued to this straight edge.

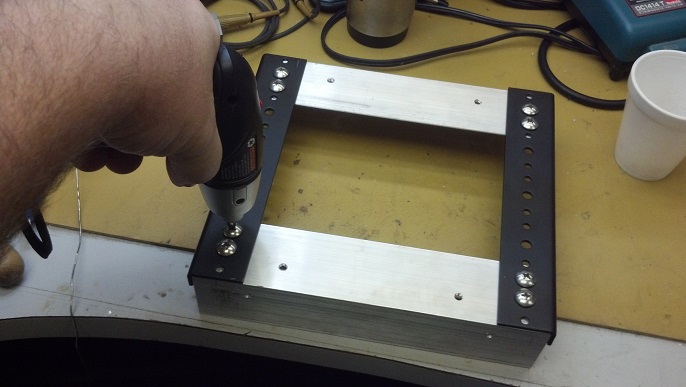

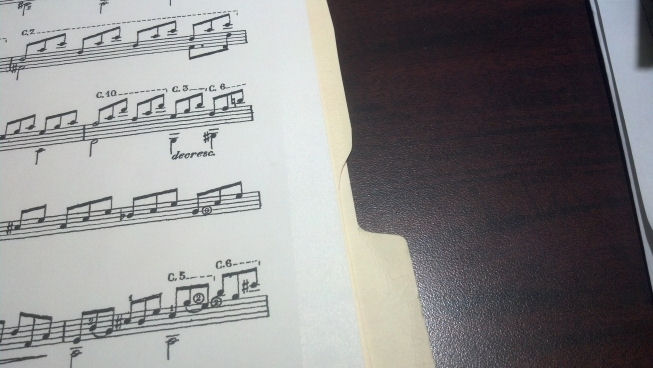

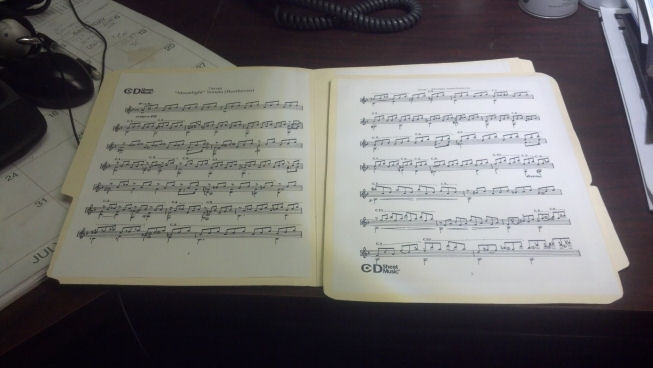

Here we are going to work with the new file. The file works best with the wide part of the blade vertical to the fret board when going along the length of the fret wire. You can see a little black magic marker on the tops of each fret wire, which serves as a visual indicator on where (and where not) to remove material.

With this file, I did not feel it was necessary to tape off the fret board because the filed particles were not small enough to lodge in the grain of the rosewood. Also, the thickness of a layer of tape would have held the blade of the file away from the corners of the fret wire ends that needed to be dressed. The fret wires were very smooth after the filing was complete, so the fret polishing was almost trivial.

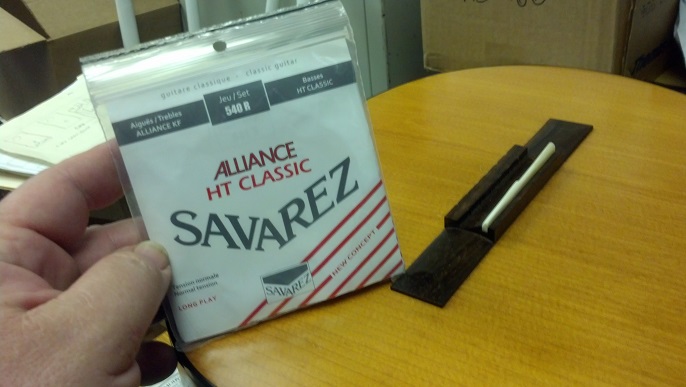

The creation of this saddle was documented in an earlier post. We’re ready to restring!

I can say that these strings are excellent! They are just a tiny bit smaller in diameter than the Augustine strings I had been using, and no intonation problems. These are a keeper!

Some customers wanted more pictures of how I tie off the classical guitar strings at the bridge tie block. Note that the ends of each string is tied underneath the loop of the string next to it. I start at string one (high E) and then secure the end in the loop of the next lower string. This looks neat and really assures me that the knot will not come loose and the string come untied.

Here, I’m taking my time to show how the last string (string six or low E) is tied off. The direction of the wrap forming the loop is in the opposite direction of the wrap used on the higher strings. This causes the free end of the E string to ‘point’ in the direction of the A string, in whose loop it shall be secured.

Now the knots in both strings are pulled tight. You can now see how the A string really holds everything in place. The end of the A string projects through the loop of string six (the low E.) We’re done here.

As I work on this guitar more and more, it gets better and better. These new strings sound wonderful. Leveling and dressing the frets make every note crisp and clean all the way up and down the fret board. The Grizzly fret file is a keeper!

Thanks for reading all the way to the end!

CONTACT: David Latchaw EE

281-636-8626