A Southeast Texas area church had a wonderful Rhodes Piano that needed some attention. Whenever the unit was powered on, a loud hum was all that came through the speakers. Time for the UnbrokenString Crew to go to work!

The Fender Rhodes Piano consists of a keyboard section, containing keys, action, and tuned rods that work in the same manner as tuning forks. The rods vibrate when struck, and the motion is sensed by a coil not unlike a guitar pickup. From there, the signal is sent to the other section, a powered stereo loudspeaker assembly seen here.

The Fender Rhodes Piano consists of a keyboard section, containing keys, action, and tuned rods that work in the same manner as tuning forks. The rods vibrate when struck, and the motion is sensed by a coil not unlike a guitar pickup. From there, the signal is sent to the other section, a powered stereo loudspeaker assembly seen here.

The speaker cabinet is two-faced e.g. loudspeakers fire from both the player’s side and the audience’s side. A pair of loudspeakers are assigned to each output of a stereo amplifier. The pairs of loudspeakers are across from each other in the cabinet, one firing forward and the other one back. This enhances the swirly, phased sound of the instrument.

The speaker cabinet is two-faced e.g. loudspeakers fire from both the player’s side and the audience’s side. A pair of loudspeakers are assigned to each output of a stereo amplifier. The pairs of loudspeakers are across from each other in the cabinet, one firing forward and the other one back. This enhances the swirly, phased sound of the instrument.

These loudspeakers are Fender branded CTS units. The metal box in the background contains power and input circuitry.

These loudspeakers are Fender branded CTS units. The metal box in the background contains power and input circuitry.

CTS built these loudspeakers in June of 1975.

CTS built these loudspeakers in June of 1975.

This part number indicates that these are 32 ohm AlNiCo loudspeakers. This is a standard-issue Rhodes Piano unit.

This part number indicates that these are 32 ohm AlNiCo loudspeakers. This is a standard-issue Rhodes Piano unit.

This voice coil is totally cooked. The motor drags badly in the magnet.

This voice coil is totally cooked. The motor drags badly in the magnet.

This voice coil is open-circuit but moves smoothly in the magnet. Is a repair possible?

This voice coil is open-circuit but moves smoothly in the magnet. Is a repair possible?

There is the broken voice coil wire. This wire is really cooked, so we will elect to replace the loudspeaker with a pair of modern 8 ohm units wired in series, to yield the proper 16 ohm load to the amplifier.

There is the broken voice coil wire. This wire is really cooked, so we will elect to replace the loudspeaker with a pair of modern 8 ohm units wired in series, to yield the proper 16 ohm load to the amplifier.

We have removed the panel at the end of the cabinet. The power transformer is visible to the right. Each channel has a separate input here. Also, a special cable from the Rhodes keyboard attaches here.

We have removed the panel at the end of the cabinet. The power transformer is visible to the right. Each channel has a separate input here. Also, a special cable from the Rhodes keyboard attaches here.

The power cord for this unit is no different than an extension cord.

The power cord for this unit is no different than an extension cord.

Instead of a regular extension cord, we will use a SmartPower unit to power-up the unit and protect it from surges. Think ‘mini-Furman unit.’ I also sell these, BTW.

Instead of a regular extension cord, we will use a SmartPower unit to power-up the unit and protect it from surges. Think ‘mini-Furman unit.’ I also sell these, BTW.

These transistors read as short circuit. I think we now know everything we need to know to make an intelligent quotation.

These transistors read as short circuit. I think we now know everything we need to know to make an intelligent quotation.

Name, rank, and serial number please.

Name, rank, and serial number please.

One output of the power supply assembly is 25vdc for the keyboard section.

One output of the power supply assembly is 25vdc for the keyboard section.

The keyboard voltage is set by a potentiometer accessible through this hole.

The keyboard voltage is set by a potentiometer accessible through this hole.

The power supply filter cap is in great shape for its age!

The power supply filter cap is in great shape for its age!

Likewise, these guys look great and test good.

Likewise, these guys look great and test good.

Everything here is as it should be.

Everything here is as it should be.

Steven removed one of the damaged loudspeakers.

Steven removed one of the damaged loudspeakers.

Over the years, the gasket glued itself to the cabinet.

Over the years, the gasket glued itself to the cabinet.

A little extra cleanup won’t hurt a thing.

A little extra cleanup won’t hurt a thing.

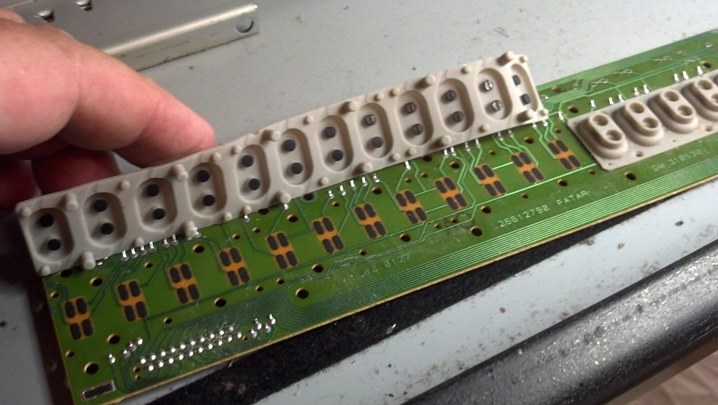

The circuit board for the power amplifier is a hand-drawn affair, typical for the 1970s.

The circuit board for the power amplifier is a hand-drawn affair, typical for the 1970s.

The board designer was nice enough to add is some text that would help the amp tech find his/her way around.

The board designer was nice enough to add is some text that would help the amp tech find his/her way around.

Some power resistors were burned up. All of the components to the right of the transformer were replaced. The transformer is for inter-stage coupling, not power.

Some power resistors were burned up. All of the components to the right of the transformer were replaced. The transformer is for inter-stage coupling, not power.

Some power transistors were hand-selected for duty in this amplifier.

Some power transistors were hand-selected for duty in this amplifier.

The repaired amplifiers are re-installed in the bottom of the cabinet.

The repaired amplifiers are re-installed in the bottom of the cabinet.

Amplifier design has certainly changed over the years. This is a unique design that has withstood the test of time very well! The customer was VERY pleased with the finished job. Weather Report Cover Band, anyone?

Amplifier design has certainly changed over the years. This is a unique design that has withstood the test of time very well! The customer was VERY pleased with the finished job. Weather Report Cover Band, anyone?

Thanks for reading all the way to the end!

CONTACT – David Latchaw EE

281-636-8626