Rod had this Peavey head kicking around and thought it was time to put it to good use. However, it didn’t work at all. Could the Unbrokenstring Crew work its magic and bring this road warrior back to life?

A quick scan of the front panel shows that the input circuit sports the sort of flexibility that the Peavey Marketing Department loves to explain to anyone who would listen…

A quick scan of the front panel shows that the input circuit sports the sort of flexibility that the Peavey Marketing Department loves to explain to anyone who would listen…

Each channel has independent gain, and a master volume to Rule Them All. Effects can be inserted via the front panel.

Each channel has independent gain, and a master volume to Rule Them All. Effects can be inserted via the front panel.

On the rear panel, we have parallel speaker jacks and the usual ground/no-ground power switching. Peavey often married different front panels, which contained preamp circuitry, to different rear panels, which carried power and audio amplifier components. The ‘series’ number goes with the power amp, not the front panel. We Got This.

On the rear panel, we have parallel speaker jacks and the usual ground/no-ground power switching. Peavey often married different front panels, which contained preamp circuitry, to different rear panels, which carried power and audio amplifier components. The ‘series’ number goes with the power amp, not the front panel. We Got This.

Name, rank, and serial number, please.

Name, rank, and serial number, please.

Pulling the front panel, we see that all of the components are mounted on one circuit board.

Pulling the front panel, we see that all of the components are mounted on one circuit board.

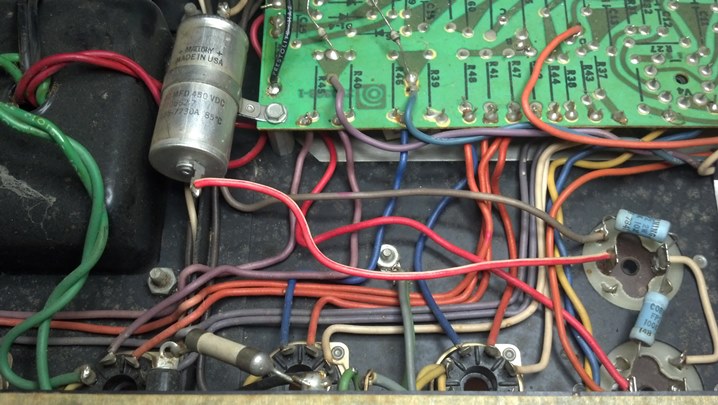

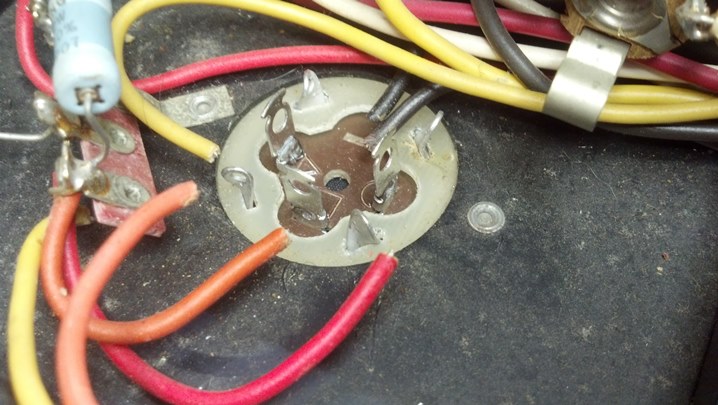

I took a few pictures to be sure that the wiring and cables were returned to the same spot when we are through.

I took a few pictures to be sure that the wiring and cables were returned to the same spot when we are through.

The cable to the right is just wired to the power indicator. The other two carry signals.

The cable to the right is just wired to the power indicator. The other two carry signals.

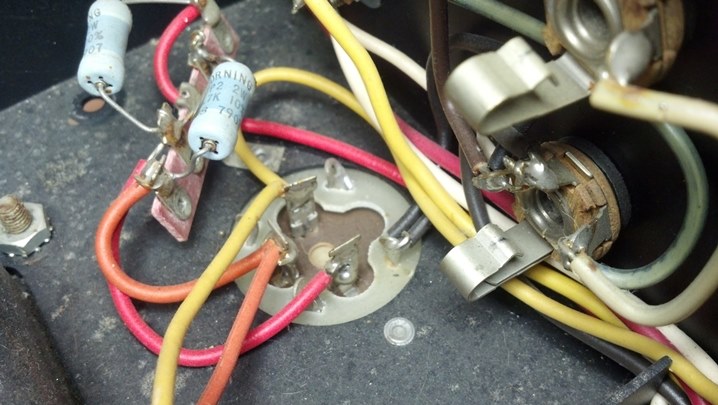

This is a better view (to be sure that they cables are properly oriented on their pins.

This is a better view (to be sure that they cables are properly oriented on their pins.

The front panel is free of the rest of the unit.

The front panel is free of the rest of the unit.

All of the controls and switches will be cleaned so this assembly comes completely apart.

All of the controls and switches will be cleaned so this assembly comes completely apart.

We can now clean and lubricate everything now.

We can now clean and lubricate everything now.

Can you spot the broken solder joints?

Can you spot the broken solder joints?

Someone has been here before! This needs to be cleaned up, too.

Someone has been here before! This needs to be cleaned up, too.

The Blue Shower is a good cleaner. The DeoxIt contains a lubricant for the potentiometers. Good Stuff!

The Blue Shower is a good cleaner. The DeoxIt contains a lubricant for the potentiometers. Good Stuff!

Back Together it all goes!

Back Together it all goes!

This screw hole was stripped out. First, we will soak the stripped hole in the wood with this wood hardener.

This screw hole was stripped out. First, we will soak the stripped hole in the wood with this wood hardener.

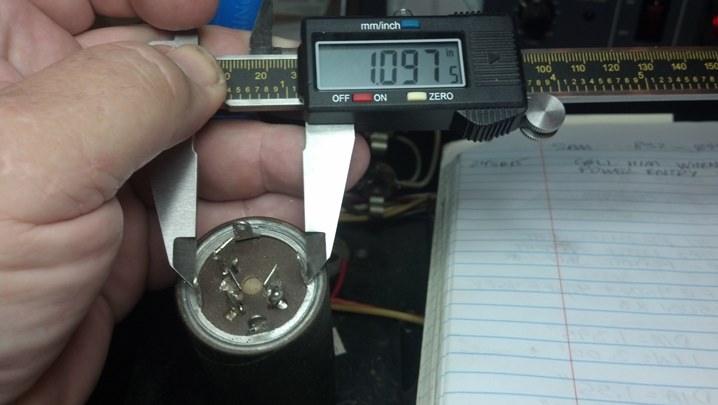

Next, a birch dowel is cut to partially fill the hole. The dowel reduces the apparent diameter, allowing the screw to hold.

Next, a birch dowel is cut to partially fill the hole. The dowel reduces the apparent diameter, allowing the screw to hold.

With the stripped hole repaired, we are back in business!

With the stripped hole repaired, we are back in business!

This unit plays very well, and all the controls and switches are Like New!

This unit plays very well, and all the controls and switches are Like New!

Thanks for reading all the way to the end!

CONTACT – David Latchaw EE

281-636-8626