Billy said that he really liked this bass, but the blend pot was coming loose and something electrical was intermittent inside the instrument. Could The Unbrokenstring Crew look it over and make it stage-worthy again?

In literary circles, the term “vanity publishing” is often applied to authors who self-publish their own works. The JR Beck line is a ‘vanity-built’ line of musical instruments, wherein an individual approaches an instrument manufacturer to build instruments under a new name. This bass likely came into the world as part of a contract with a Korean manufacturer.

In literary circles, the term “vanity publishing” is often applied to authors who self-publish their own works. The JR Beck line is a ‘vanity-built’ line of musical instruments, wherein an individual approaches an instrument manufacturer to build instruments under a new name. This bass likely came into the world as part of a contract with a Korean manufacturer.

The neck is straight and the frets are level. This is a player’s six string bass.

The neck is straight and the frets are level. This is a player’s six string bass.

The head stock shape reminds me of an Ibanez profile.

The head stock shape reminds me of an Ibanez profile.

The Grover tuners are really nice.

The Grover tuners are really nice.

Someone has been here before. This screw is too long for the hole.

Someone has been here before. This screw is too long for the hole.

Just how deep does the hole need to be? It needs to be THIS long.

Just how deep does the hole need to be? It needs to be THIS long.

We will bore this hole down to the tape go get the length we want.

We will bore this hole down to the tape go get the length we want.

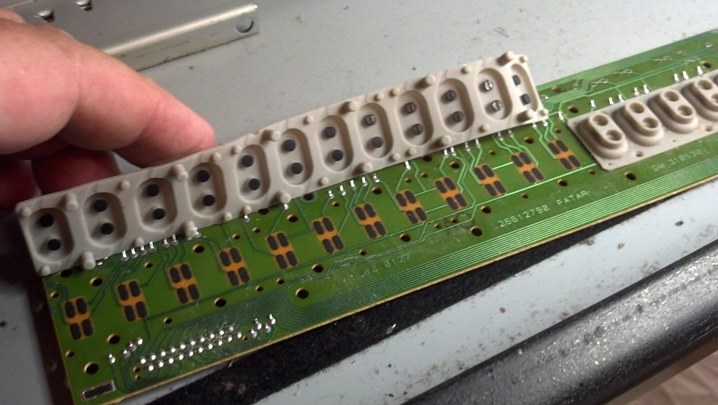

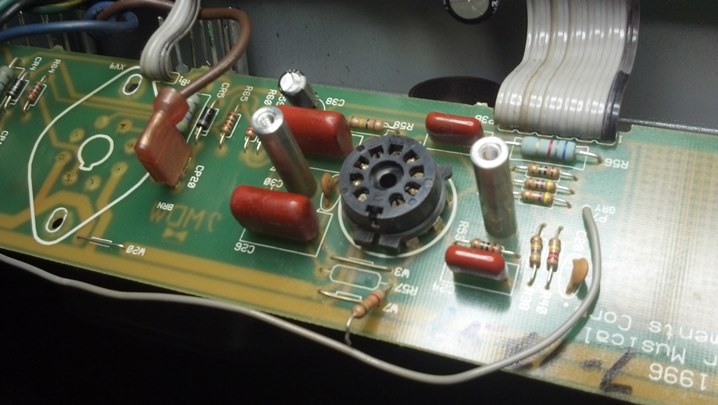

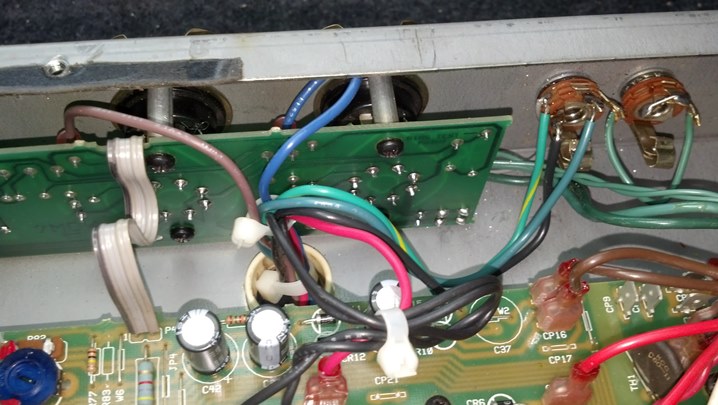

I can find no markings on the preamp electronics. The rest of the wiring is a mess around the blend pot.

I can find no markings on the preamp electronics. The rest of the wiring is a mess around the blend pot.

The duct tape did NOT come from Korea. Why not get someone who can do this sort of work cleanly, like me?

The duct tape did NOT come from Korea. Why not get someone who can do this sort of work cleanly, like me?

The blend pot is a hack job. The rest of the wiring is probably as it was from the factory.

The blend pot is a hack job. The rest of the wiring is probably as it was from the factory.

Use more solder if you don’t solder it right the first time. The solder has actually flowed inside the unit and mechanically interferes with the rotation of the wiper in one of the sections of the control.

Use more solder if you don’t solder it right the first time. The solder has actually flowed inside the unit and mechanically interferes with the rotation of the wiper in one of the sections of the control.

We’ve removed the wires from the blend pot. The cables with the green and yellow jacket come from the pickups. The cable with the white jacket wire goes to the active electronics.

We’ve removed the wires from the blend pot. The cables with the green and yellow jacket come from the pickups. The cable with the white jacket wire goes to the active electronics.

Some RTV was used in an attempt to stabilize the front face of the blend control and keep it from moving when the knob was twisted. What a mess.

Some RTV was used in an attempt to stabilize the front face of the blend control and keep it from moving when the knob was twisted. What a mess.

As the control moved around, it scored up the wood body of the bass. No pick guard on this unit.

As the control moved around, it scored up the wood body of the bass. No pick guard on this unit.

To stabilize the wood and prep to mount a new control in a stable manner, a Forstner bit is employed to create a flat-bottomed ‘spot face’ in the wood cavity. There is some risk of penetration, so we’re going slowly at this point.

To stabilize the wood and prep to mount a new control in a stable manner, a Forstner bit is employed to create a flat-bottomed ‘spot face’ in the wood cavity. There is some risk of penetration, so we’re going slowly at this point.

A flat-bottom hole is bored without incident. A steel washer will be epoxied into the body to fully-support the new blend pot.

A flat-bottom hole is bored without incident. A steel washer will be epoxied into the body to fully-support the new blend pot.

The new blend pot comes with a couple of flat washers. I’ll use a lock washer and another nut to set the height of the control so that the knobs are all installed at the same height on the face of the guitar.

The new blend pot comes with a couple of flat washers. I’ll use a lock washer and another nut to set the height of the control so that the knobs are all installed at the same height on the face of the guitar.

A blend pot is a pair of “M” taper potentiometers, which allow one pickup to be faded out as the other side gets louder. As the control reaches each limit of its travel, the other pickup is electrically ‘cut out’ of the circuit. In a way, it acts as a selector switch at each end of the travel, with a continuous blend of the two signals in between.

A blend pot is a pair of “M” taper potentiometers, which allow one pickup to be faded out as the other side gets louder. As the control reaches each limit of its travel, the other pickup is electrically ‘cut out’ of the circuit. In a way, it acts as a selector switch at each end of the travel, with a continuous blend of the two signals in between.

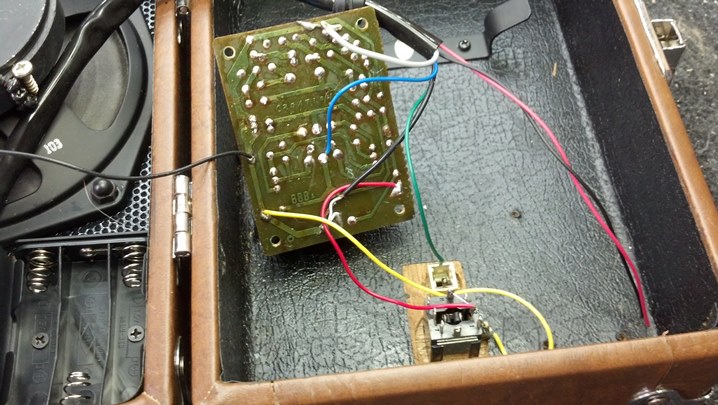

The cross wiring is done with solid 20AWG copper covered with Teflon tubing. The pickups are wired on the end.

The cross wiring is done with solid 20AWG copper covered with Teflon tubing. The pickups are wired on the end.

This control has an index pin. We will cut a slot in the steel washer to ‘catch’ this index pin and hold everything in place.

This control has an index pin. We will cut a slot in the steel washer to ‘catch’ this index pin and hold everything in place.

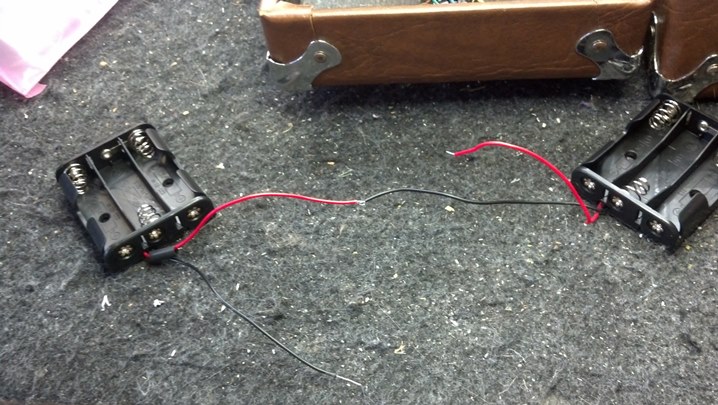

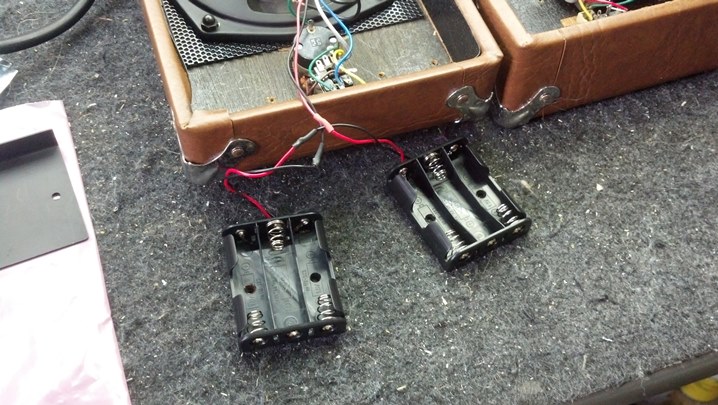

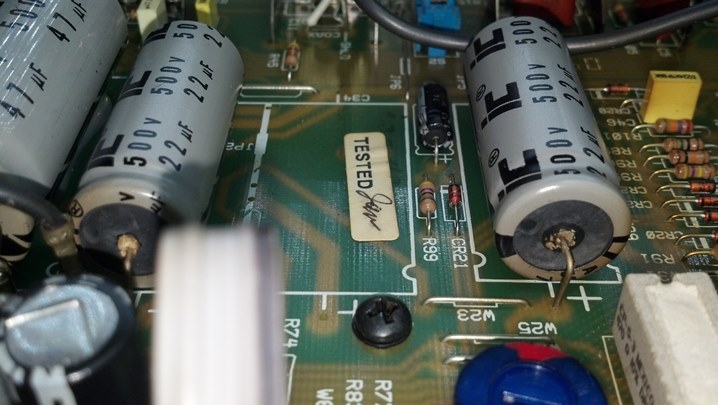

Initial tests showed that the signals from both pickups were literally ‘grounded’ when the control was set to either limit. We need to install range-limiting resistors to each end of the controls so that the selected pickup is not grounded at the end of the potentiometer travel. This is a blend pot, not a kill switch, after all.

Initial tests showed that the signals from both pickups were literally ‘grounded’ when the control was set to either limit. We need to install range-limiting resistors to each end of the controls so that the selected pickup is not grounded at the end of the potentiometer travel. This is a blend pot, not a kill switch, after all.

It is an easy task to break the connection to ground and install a fixed resistor. The proper value depends, in part, on the internal DC resistance of each pickup. It will be easier to discover the proper value empirically.

It is an easy task to break the connection to ground and install a fixed resistor. The proper value depends, in part, on the internal DC resistance of each pickup. It will be easier to discover the proper value empirically.

The box with all the switches is sometimes called a ‘design box.’ The proper name is a ‘resistance substitution box.’ Various values of resistors are switched into the circuit until the desired result is obtained. Here, we are choosing a resistor value for one side of the blend pot. Too low a value attenuates the signal. Too high a value causes hum.

The box with all the switches is sometimes called a ‘design box.’ The proper name is a ‘resistance substitution box.’ Various values of resistors are switched into the circuit until the desired result is obtained. Here, we are choosing a resistor value for one side of the blend pot. Too low a value attenuates the signal. Too high a value causes hum.

Here is the fixed resistor for this side of the blend pot. Note the use of the Teflon tubing to keep the signals under control.

Here is the fixed resistor for this side of the blend pot. Note the use of the Teflon tubing to keep the signals under control.

Here is the new control installed in its new home. I am satisfied with the electrical results of this experiment.

Here is the new control installed in its new home. I am satisfied with the electrical results of this experiment.

The original knob works nicely with the new control. Note that the knobs are all the same height off the body of the bass. Another thing I like about this bass is, look at that massive bridge saddle and end block! The Koreans really know how to do it right.

The original knob works nicely with the new control. Note that the knobs are all the same height off the body of the bass. Another thing I like about this bass is, look at that massive bridge saddle and end block! The Koreans really know how to do it right.

Jacob takes the finished bass for a spin. He wants one!

Jacob takes the finished bass for a spin. He wants one!

Thanks for reading all the way to the end!

CONTACT – David Latchaw EE

281-636-8626