The Unbrokenstring Crew knew that it would only be a matter of time before gear submerged in Hurricane Harvey’s floods came onto the secondary market, be it CraigsList, OfferUp, or even as used gear at a national retail music chain that I will not name here, but go by the initials “Guitar Center.”.

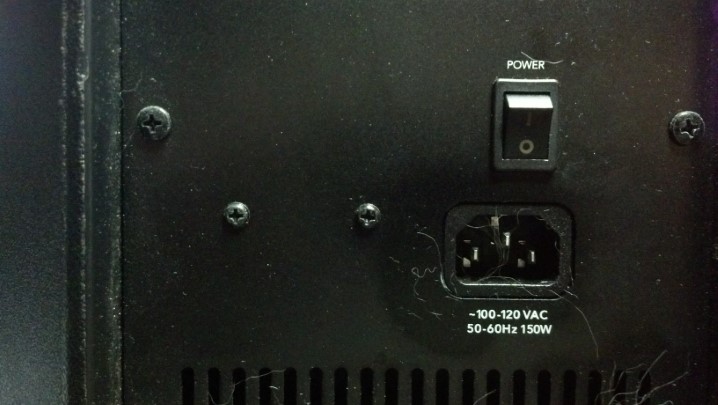

Who could turn down this awesome piece of gear at a great used-equipment price? But this guy blow fuses.

Who could turn down this awesome piece of gear at a great used-equipment price? But this guy blow fuses.

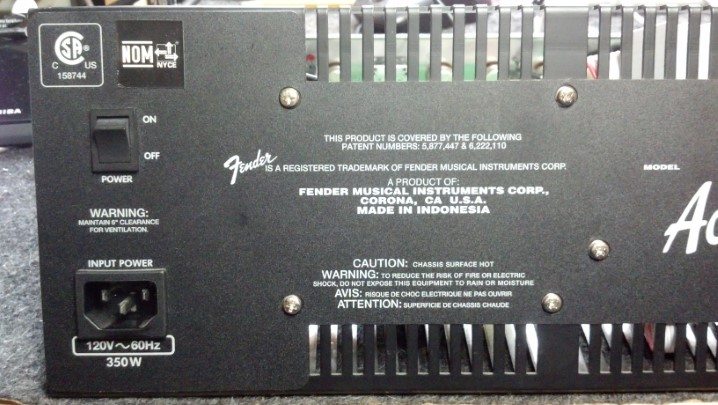

Carvin is an excellent brand. Their musical instruments are expertly crafted, and the electronics are top drawer. And this amp head has three channels!

Carvin is an excellent brand. Their musical instruments are expertly crafted, and the electronics are top drawer. And this amp head has three channels!

The rear panel of this unit shows all the versatility you could possible ask for in a tube head.

The rear panel of this unit shows all the versatility you could possible ask for in a tube head.

The select-able tetrode/pentode bias switch and a ‘cabinet-voiced’ line out signal jack are cool touches.

The select-able tetrode/pentode bias switch and a ‘cabinet-voiced’ line out signal jack are cool touches.

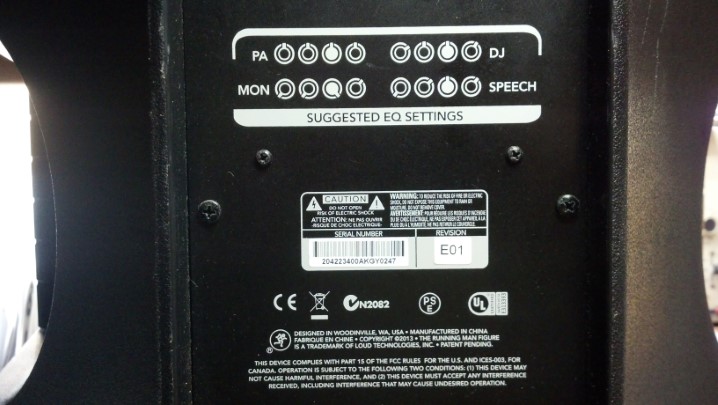

Serial number, for those who are curious.

Serial number, for those who are curious.

The tube chart is silk-screened right on the chassis.

The tube chart is silk-screened right on the chassis.

But when we open the unit up and turn it over, we see rust. Some of the tan residue is rosin solder flux, which is OK. But at the very top of the picture is a black pit in the end of a socket pin, which has almost entirely rusted away and will require replacement. Most electrical component leads have a core of iron, which is then tin plated for solder-ability. If the tin is intact, water is not an issue. But how many component leads have literally rusted away? Has this unit been wet?

But when we open the unit up and turn it over, we see rust. Some of the tan residue is rosin solder flux, which is OK. But at the very top of the picture is a black pit in the end of a socket pin, which has almost entirely rusted away and will require replacement. Most electrical component leads have a core of iron, which is then tin plated for solder-ability. If the tin is intact, water is not an issue. But how many component leads have literally rusted away? Has this unit been wet?

The reverb tank is functional, but shows signs of water exposure.

The reverb tank is functional, but shows signs of water exposure.

These springs are very hard steel, so they rust and deteriorate very quickly.

These springs are very hard steel, so they rust and deteriorate very quickly.

Confirming our wet theory, the Tolex on the bottom of the case is coming loose.

Confirming our wet theory, the Tolex on the bottom of the case is coming loose.

Did I remove those screws and not notice the rust?

Did I remove those screws and not notice the rust?

Looking closely at the hold-down clips for the tubes, they are completely rusted.

Looking closely at the hold-down clips for the tubes, they are completely rusted.

The steel chassis is coated in white enamel, which is really Top Drawer. But receding flood waters left mud.

The steel chassis is coated in white enamel, which is really Top Drawer. But receding flood waters left mud.

Tear-down is in order to assess the condition of the unit.

Tear-down is in order to assess the condition of the unit.

This is the component side of the circuit board that holds the power tube sockets. All this crusty solder flux tells me that the rosin is ‘activated’ with phosphorus, a Good Thing to make good solder joints, but a Bad Thing if it gets wet.

This is the component side of the circuit board that holds the power tube sockets. All this crusty solder flux tells me that the rosin is ‘activated’ with phosphorus, a Good Thing to make good solder joints, but a Bad Thing if it gets wet.

The preamp tube sockets show the same reaction with the phosphorus. This will all need to be cleaned and reworked. Some of these leads are completely hollow as the iron core has rusted away. It will be better to replace the sockets.

The preamp tube sockets show the same reaction with the phosphorus. This will all need to be cleaned and reworked. Some of these leads are completely hollow as the iron core has rusted away. It will be better to replace the sockets.

Electrical problems around the circuit board caused the preamp tube on the left to overheat.

Electrical problems around the circuit board caused the preamp tube on the left to overheat.

A complete overhaul and rebuild of this unit would be necessary to restore functionality and reliability. Most components should be replaced, including sockets and connectors. However, the customer purchased this amp because it was in his price range. The repair quotation was not in his price range.

If you are shopping for gear and see signs of water damage, such as loose Tolex, rusty hardware, or dried dirt where it shouldn’t be, you should consider having a tech go over the equipment to assess the condition and find potential reliability problems before you buy. Rusty transformer laminations are particularly troublesome, as the rust pierces the insulating coating between laminations and allows eddy currents to flow, potentially overheating the transformer. Transformers are expensive to replace.

Thanks for reading all the way to the end!

CONTACT – David Latchaw EE

281-636-8626